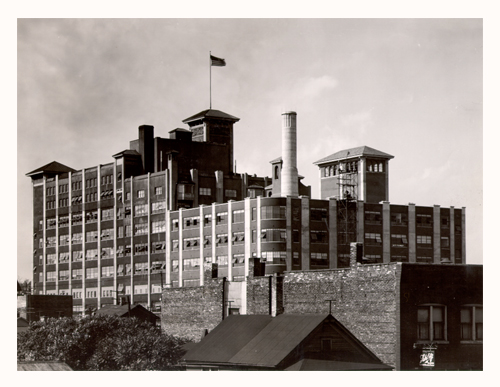

The Allen-Bradley® Clock Tower, part of the Rockwell Automation headquarters, is an iconic piece of the Milwaukee skyline and a symbol of the city’s rich industrial and technological heritage.

For 120 years, Rockwell Automation has been innovating and engineering solutions that advance industrial automation – allowing manufacturers around the globe to optimize production, empower workers, build business resiliency, and drive sustainability.

Where it all began

In 1903, Lynde Bradley and Dr. Stanton Allen filed the company’s inaugural patent. Shortly after, Harry Bradley joined his brother in business. Since then, the company has filed for nearly 7,000 patents globally and despite growing to more than 29,000 employees all around the world, maintained its friendly and family-oriented Midwest values.

Early innovations

Quickly establishing a reputation for reliability, Allen-Bradley electrical products and components found their way into most manufacturing facilities. Some even made their way to the moon and back on the Apollo 13 mission! As manufacturing practices evolved, so too did Rockwell Automation.

In 1970, the company coined the term PLC (Programmable Logic Controller) when it launched the first-ever programmable controllers. This innovation would forever change the manufacturing industry by increasing manufacturing productivity, quality, and flexibility.

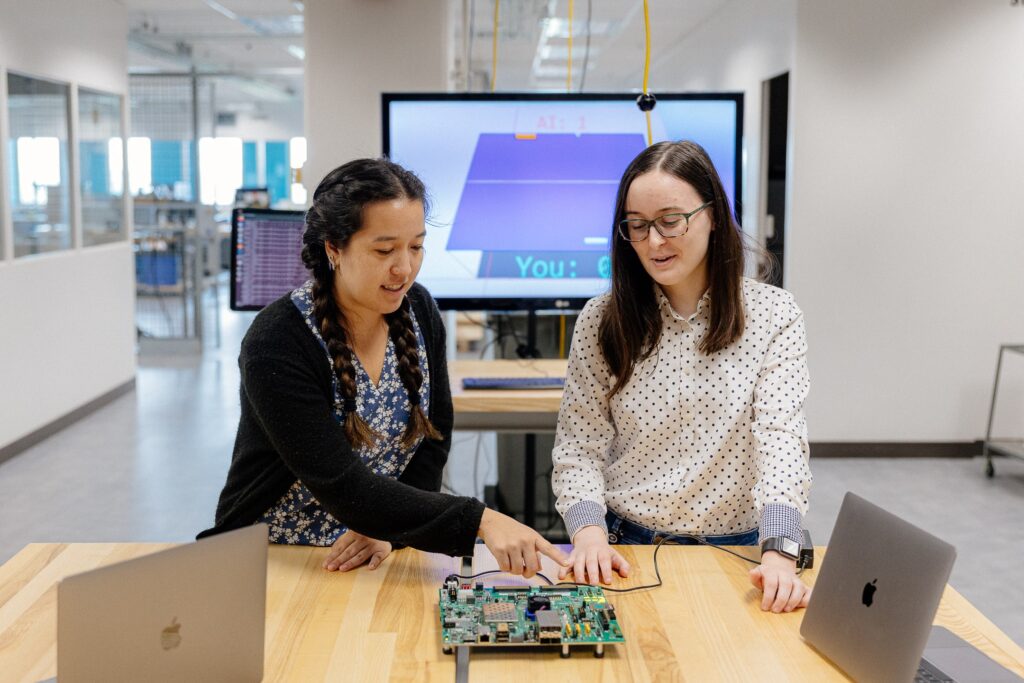

Navigating the digital landscape

As the world transitioned into the digital era, Rockwell Automation once again seized the opportunity to lead. The company launched connected smart devices that opened new windows of visibility into processes. They focused on helping industrial companies harness data and analytics to enable better and faster decision making. And they leveraged the latest technological advances like robotics, digital twins, and artificial intelligence to help drive digital transformation.

By embracing digital technologies, Rockwell Automation enabled the manufacturing industry to take a big leap forward to become more resilient, agile, and sustainable.

The future is green

The Rockwell Automation mission extends beyond industrial automation to include a deep-rooted commitment to building a sustainable future. Smart manufacturing technologies play a critical role in driving environmental, social, governance and sustainability success. Creating automation solutions for manufacturers requires fresh thinking to address the needs of a changing world. Technology plays an enabling role, but people remain the stars.

Thank you to MKE Tech for making this book possible, they are the voice and champion of Innovate® Milwaukee that unifies the community!

Makers wanted

As a part of the Rockwell Automation community, you won’t just be contributing skills to projects; you’ll be part of a legacy that spans over a century.

Rockwell Automation innovations redefine industries, from automotive manufacturing to pharmaceuticals, from oil and gas to renewable energy. It’s a place for those who want to make an impact by experimenting, pushing, questioning, and persisting. Those who desire to make the impossible possible.

Because we know that when you combine the imaginations of people with the potential of technology, anything is possible.