On 12 March 1996, Renault Group chose Paraná as the site for its new plant, marking the start of a new chapter in automotive history for Brazil. On 4 December 1998, the Ayrton Senna industrial complex opened its doors in Curitiba, becoming one of Renault Group’s main sites in South America. Over the past 25 years, the plant has achieved industrial success, building iconic vehicles and becoming part of the local socio-economic fabric. Today, the Ayrton Senna complex is beginning a new phase in its existence.

The city of Curitiba in Brazil is steeped in a passion for cars. Extending over an area of 250 hectares, the Ayrton Senna complex is part of this rich automotive culture. The complex takes its name from the legendary Brazilian driver, a triple Formula 1 champion who tallied his first victories in a Lotus powered by a Renault V6 turbo engine. The industrial saga began in 1996, when Renault Group decided to build a plant here. Inaugurated in 1998, the site is celebrating 25 years of activity and looking ahead to a bright future.

The Ayrton Senna site has reinvented itself constantly over the years, addressing the challenges of digitalization, low carbon and competitive performance. This far-reaching transformation began in 2016 with a series of initiatives relating to Industry 4.0.

First, the complex deployed a Wi-Fi infrastructure covering an area of 6,000 m2, for full connectivity across the site. The complex has also gone paperless by distributing tablets to all manufacturing staff, generating total savings of 2.5 million sheets, the equivalent of 21 tonnes of CO2.

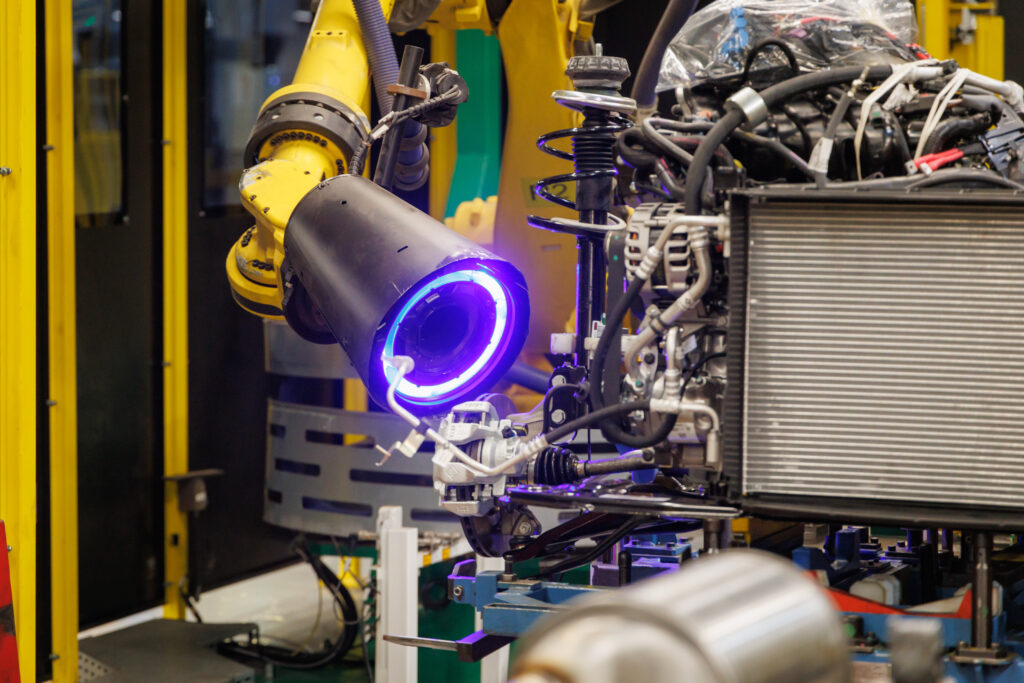

Another key milestone in the digital transformation of the production plants is the launch of the Industrial Metaverse. Today, the Ayrton Senna complex has entered a new era, with over 700 robots controlled by this cutting-edge technology. The introduction of digital twinning technology (modelling of physical resources) on assembly lines has revolutionised real-time data analysis, boosting manufacturing performance and improving quality.

Every day, an impressive total of 26,000 images are submitted to the AI process, feeding into a continuous stream of data that is used to verify powertrain quality and safety.

A 3D printing centre has also been set up, producing over 10,000 parts a year. These parts are not only used in the manufacturing process, but also to carry out a range of tests before the start of production.

To increase agility and performance, no fewer than 346 AGVs (automated guided vehicles) travel up and down the production lines every day.

In 2020, the Ayrton Senna complex was recognised as an Industry 4.0 site by the prestigious World Economic Forum foundation, once again highlighting Renault’s ongoing commitment to moving its plants towards more connected and more sustainable production.

In addition to producing cars, Renault is a reference in Brazil in mobility projects. An example is the electric taxi in Curitiba. In March/23, in a strategic partnership with ABDI (Brazilian Agency for Industrial Development) and URBS (Urbanização de Curitiba S/A), Renault and Mobilize, Renault Group brands launched a project to use electric vehicles as taxi in the city of Curitiba. Six 100% electric Renault Zoe E-Tech vehicles were delivered to taxi drivers, chosen by URBS to participate in the project.