Founded in 1996, DeltaHawk Engines, Inc. has always been driven by innovation and a determination to revolutionize aviation propulsion. Specializing in general aviation, military, uncrewed, and hybrid applications, DeltaHawk’s engines are a testament to ingenuity, reliability, and efficiency. In 2023, the company made history by achieving FAA Type Certification for its DHK engines—the first clean-sheet piston engine design to earn this distinction in over 60 years. This milestone was more than a triumph for DeltaHawk; it marked a new era in aviation.

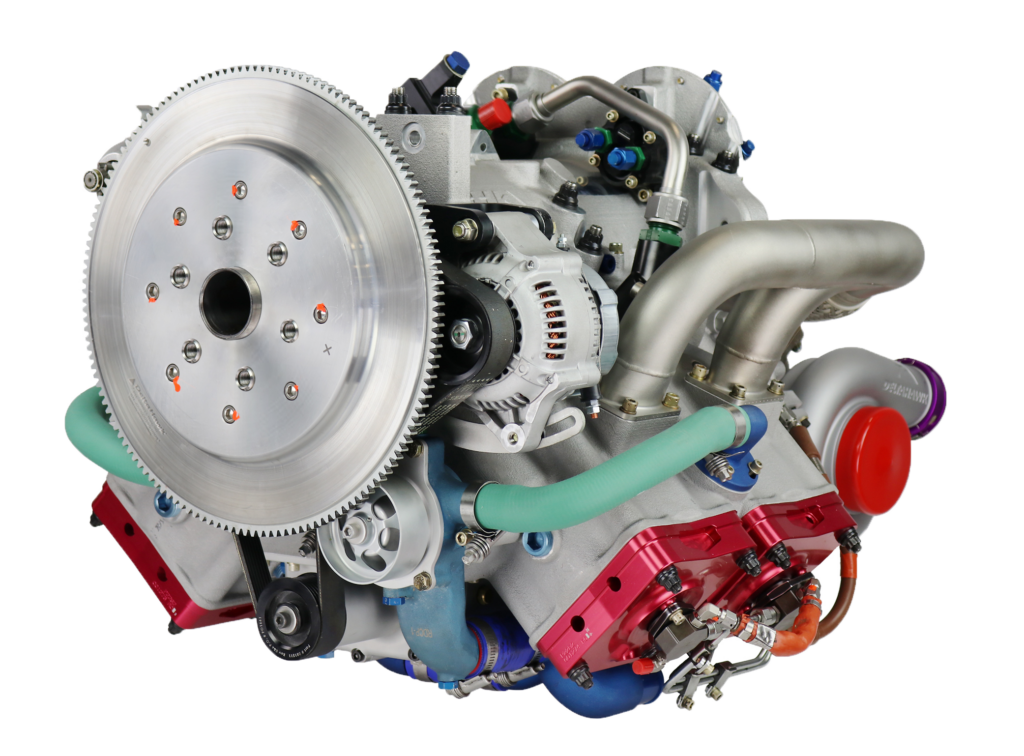

“We have created an entirely new class of engine: a lightweight, compact kerosene-based piston engine that operates on jet fuel, diesel, and military-grade fuels,” says CEO Chris Ruud. “The DeltaHawk engine makes better, more reliable power in less space and with fewer moving parts. These engines are like nothing that has come before in terms of safety, efficiency, and performance.”

Built by Visionaries, Perfected Through Perseverance

DeltaHawk’s origin story is one of relentless determination. Founded by Doug and Diane Doers and John “JP” Brooks, the company set out to create a modern engine that would deliver cleaner, more efficient performance while requiring less maintenance. With backgrounds in military aviation, civilian piloting, and mechanical engineering, the founders had the expertise but faced considerable challenges. Progress was slow, often hindered by limited funding and technical complexities.

The tide turned in 2015 when Chris and Al Ruud became aware of DeltaHawk’s potential. Sharing the founders’ vision, the Ruuds provided financial backing and strategic direction, enabling the company to achieve its ambitious goals. Over $100 million has since been invested in DeltaHawk’s facilities, personnel, and rigorous testing protocols, cementing its status as a technical leader in aviation propulsion.

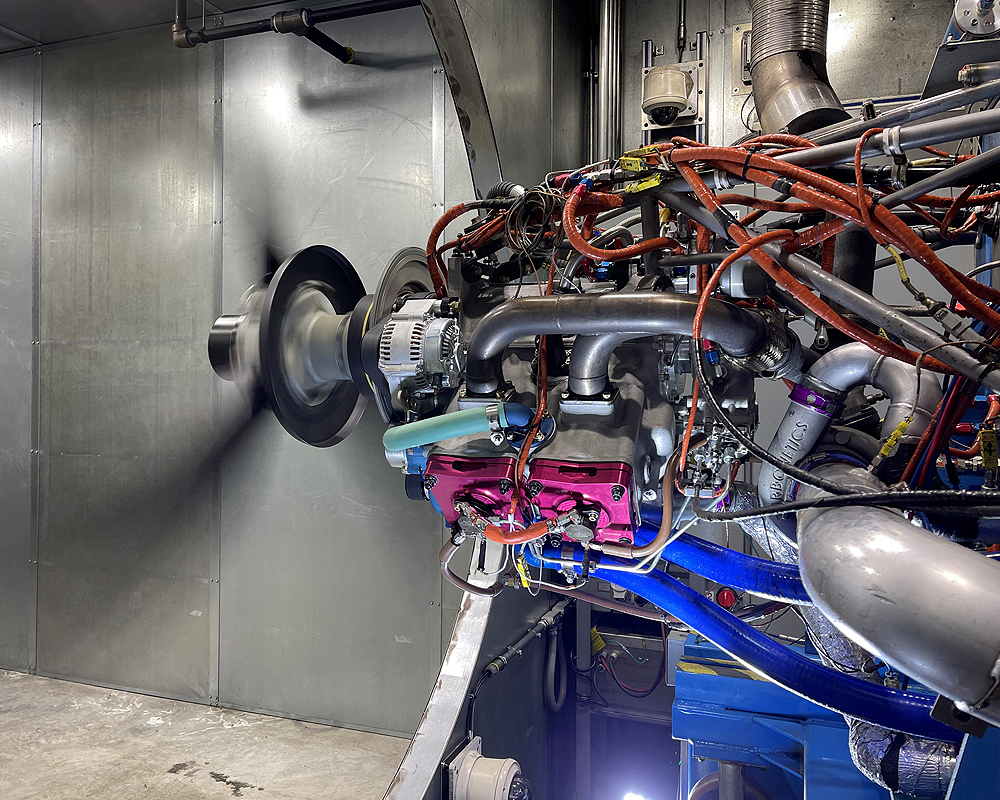

Today, DeltaHawk operates out of an 85,000-square-foot campus adjacent to Batten International Airport (KRAC) in Racine, Wisconsin. “We design, assemble, and test virtually every critical component of our engines in-house,” says Jon Heup, President of DeltaHawk. “This level of control ensures unparalleled quality throughout the build process.”

Reinventing the Standard in Aviation Power

DeltaHawk’s DHK engines epitomize simplicity and elegance, embodying Leonardo da Vinci’s principle that simplicity is the ultimate sophistication. The engines’ compact, lightweight design offers superior reliability and performance across a range of applications, from retrofitting existing aircraft to hybrid-electric solutions for cutting-edge designs.

“On the average mission, a jet-fueled DeltaHawk engine is up to 40%more efficient than an Avgas engine,” explains Dave Gill, Director of Engineering. “This translates to improved range, increased payload capacity, and lower costs of ownership. The engine’s small, aerodynamic profile further boosts fuel efficiency, while multiple redundancies enhance safety. And with jet fuel’s global availability, you can fly anywhere without worrying about refueling logistics.”

Attributes That Define Excellence

DeltaHawk’s DHK engines are built to surpass industry standards, offering:

- Ease of Use: Single-lever control, effortless cold-weather starts, and shock-free cooling.

- Cost Efficiency: 35-40% lower fuel consumption than Avgas engines, simplified maintenance, and fewer moving parts for reduced overhaul costs.

- Fuel Versatility: Compatibility with jet fuel, diesel, and Sustainable Aviation Fuel (SAF).

- Exceptional Safety: Redundant systems, a cooler operational profile, and no risk of CO cabin heating.

- Performance Under Pressure: Turbocharged and supercharged capabilities, excellent low-end torque, and high-altitude reliability.

- Eco-Friendliness: 35-40% less fuel consumption, no lead emissions, and readiness for carbon-neutral SAF.

From Retrofit to Revolution

DeltaHawk’s versatility shines through its diverse range of applications. For retrofits, the DHK engines significantly reduce fuel burn, simplify operation, and enhance safety. “Our Engine Propulsion Packages are more than just engines,” shares Andy Oja, Airframe Integration Manager. “They include all necessary components—heat exchangers, pumps, filters, cowlings, and installation kits—tested and ready for seamless integration.”

For Original Equipment Manufacturers (OEMs), the DeltaHawk engine’s streamlined cowl design and lighter weight are game changers. Military applications further highlight the engine’s adaptability. Whether powering uncrewed aerial systems, lightweight marine craft, or integrated power-generation packages, DeltaHawk engines deliver unparalleled performance in mission-critical scenarios.

The Future of DeltaHawk

Looking ahead, DeltaHawk is poised to lead the aviation industry into a sustainable future. With FAA certification secured, the company is focused on expanding its applications in hybrid-electric aviation and supporting global efforts to adopt SAF.

“Our mission doesn’t stop at revolutionizing aircraft propulsion,” Chris affirms. “We are committed to providing solutions that meet the evolving needs of aviation while reducing environmental impact. DeltaHawk will continue to push the boundaries of what’s possible, setting new standards for innovation, safety, and performance.”

By reimagining power through time-proven innovation, DeltaHawk is not just building engines; it’s reshaping the future of flight.