If you see a portable tower that can…

- Take a 3,600 lb, 10-foot-diameter wind turbine and raise it up to 80 feet in less than 5 minutes,

- Hold a large device at 80 feet in the air during a hurricane without being tied to the ground,

- Be fully deployed (or removed) at a site in 15–20 minutes

…that can ONLY could be a Tower Solutions tower!

,

Just a Quick Note:

InnovationsOfTheWorld.com has partnered with Trade License Zone (TLZ) to support global innovators looking to expand internationally. Take advantage of the UAE’s Free Zones—enjoy streamlined setup, low corporate taxes, and a strategic gateway to the Middle East and beyond.

Get Your UAE Free Zone License Fast & Easy!

Formed in 1999, Tower Solutions delivered its first trailered Large Tower Series (LTS) PTM-100 model tower in 2001. That tower is now owned and still utilized by Verizon during events to add additional cellphone lines. This first model has gone on to be a household name in several applications like the US Air Force Predator Program. Later, a similar but more compact version was developed as the PTM 130, which allows transport in a C-130 cargo plane.

In 2017, the heavy duty and unshakeable PTX-100 large tower was introduced, which can survive over 100 mph winds. Utilizing combinations of generators solar or fuel cells to recharge batteries, and huge outrigger supports that have guy wires attached, this “Green” tower can be installed at a site in 2 hours and later removed with almost no impact on the environment.

,

In 2020, Tower Solutions is going to new heights with its new heavy duty

towers which extend to up to 120 feet, rivaling the performance of some

fixed tower installations.

With the LTS towers outperforming the competition, the small tower

series (STS) was introduced, offering small to medium-sized vehiclemounted, automatic self-leveling, and payload protection, as well as

multiple support options.

- The agile STS-6 which fits well on an ATV, deploys up to 150 lbs, and extends to 20 feet

- The robust and versatile STS-12, is designed for a pickup bed, holds up to 500 lbs and deploys up to 33 feet

,

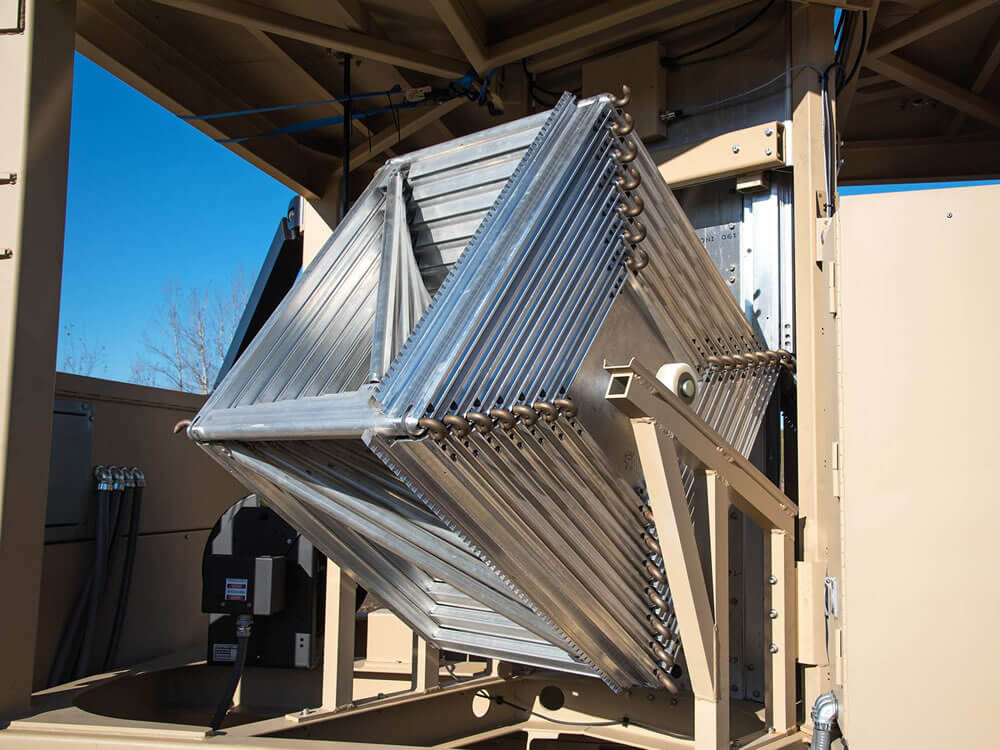

Tower Solutions’ unique and patented tower module features three sides

of the tower, separately stowed on square spools. The tower assembles

itself as it deploys upward and disassembles itself when it comes down. A

heavy-duty hooking system ties the sides of the towers together during

deployment and creates a near-contiguous, highly rigid tower that offers

minimal movement in windy environments.

A sophisticated control system takes advantage of the unique qualities of

the tower module provides standard and optional features, such as:

- Simple UP/DOWN two-button controls

- Sophisticated sensor-operator interface that monitors & reports tower operational status

- Ability to stop the tower at any height with high accuracy and repeatability

- Facilitates line of sight communications

- Allows the payload to be lowered for safe repair or maintenance, and returned to required height

- Fine tuning adjustment available on the height

- WindStableTM—Ability for the tower to automatically monitor environmental conditions, anticipate dangerous winds, lower the tower to a safe height, and return the tower to operating height when safe winds resume. The system also can notify an operator or central control site of the incident.

- TowerTalkTM—Tower communications between users of single or

multiple towers that offer the ability to:

- Remotely operate a tower

- Share tower health information and relay back to a central control

site - Synchronize towers to raise and lower together

Also offered are means for easily loading of a payload on top of a tower, power-management systems and sources, cable management, electronics enclosures, workplace and operational safety, and advanced trailering features. Finally, Tower Solutions products are highly adaptable for specialized use and customer specific needs. Located in the twin cities of Minnesota, Tower Solutions headquarters is 10 minutes from the MSP International Airport at:

Raising Performance with the push of a Button

,