Flexible Hybrid Electronics (FHE) are a demanding environment for reliable interconnects and component attachment on the Printed Electronics world. FHE is typically comprised of the combination of simple printed circuitry made with conductive inks and more complex

electronics using microchips, and other high functionality components like LED’s and resistors. These components have traditionally been connected to rigid circuit boards with solder, and more recently onto flexible substrates with Electrically Conductive Adhesives (ECA’s). These technologies have shortcomings when used in high performance FHE applications. While solders provide the most conductive electrical connection, they are rigid and require the addition of an underfill adhesive as well as a post bond encapsulation. ECA’s are less conductive, and also require underfill and/ or over encapsulation. SunRay Scientific of Eatontown, NJ has developed ZTACH® ACE to provide reliable interconnections between electronic components and circuitry on flexible and even stretchable substrates, without encapsulation, even under repeated mechanical stress. ZTACH® ACE has been shown as a scalable assembly process for FHE manufacturing in an SMT line.

Anisotropic electrically conductive adhesive compatible with automated SMT Processing

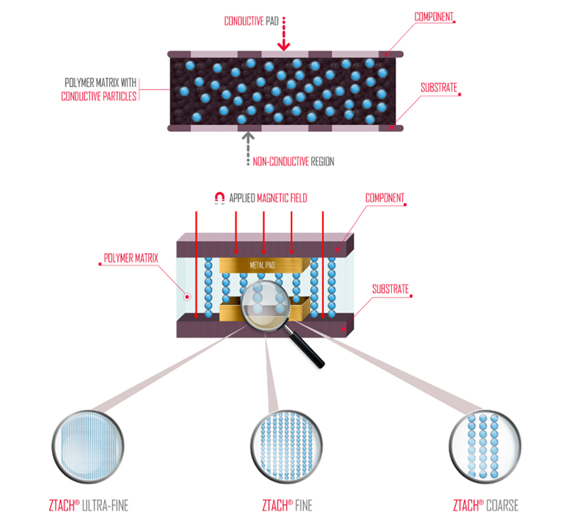

ZTACH® ACE, an Anisotropic Conductive Epoxy, allows for simultaneous Z-axis connections of all the devices on a board, sheet, or textiles, across large formats. It requires no patterning, no bonding pressure, and can be cured at low temperatures. ZTACH® ACE can adhere to a wide range of substrates, including PET, TPU, various textiles and PCBs. This material acts as its own underfill, providing superior adhesion and shear strength, eliminating the need for a secondary underfill or post-bond encapsulation. ZTACH® ACE can achieve fine pitch down to 100-microns. Less than 50 microns pitch is currently in development.

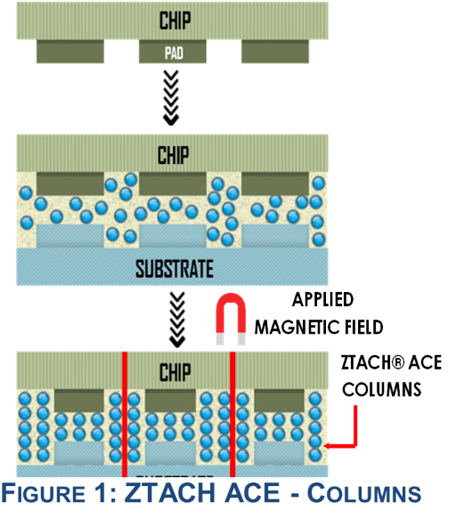

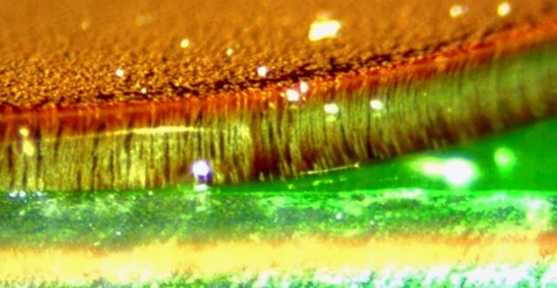

ZTACH® ACE works by the magnetic alignment of ferromagnetic conductive particles through SunRay’s patented ZMAG™ magnetic pallet. As illustrated in Figure 1, once placed on the ZMAG™ Pallet, these particles immediately align into z-axis “wires” magnetically held in place while the resin is hardened by the curing process. This electrically connects the device to the circuit. Because of the very low particle filler percentage, the resin creates exceptionally higher bond strength for the device versus traditional attachment methods. Since ZTACH® ACE is basically an underfill with conductive Z-axis columns throughout, it creates electrical conductivity at the pad locations and thermal dissipation between – all done while maintaining electrical insulation in the X-Y plane.

Good performance of ZTACH® ACE has been demonstrated through thousands of components interconnected on hundreds of sheets on high volume SMT/reflow lines.

ZTACH® ACE overcomes limitations of conventional solders

Unlike solder, ZTACH® ACE provides both the electrical connection and the underfill.

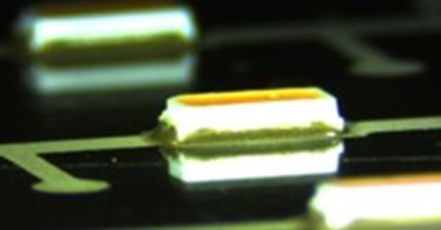

Most solder connections on a flexible substrate traditionally require the addition of an encapsulant for protection and for maintaining adhesion of the less flexible interconnection joints. ZTACH® ACE has demonstrated reliability without the need for an encapsulant. This eliminates a manufacturing step and the localized rigidizing created by an encapsulant, with a less bulky product profile. No encapsulant is especially beneficial in LED applications as the clarity of the LEDs are not interfered by the addition of an optically clear covering. Nor is the performance over time impacted by the aging characteristics of an encapsulating material. This is particularly useful for the optimal performance of UV LEDs in medical applications.

Wearable electronics present challenges beyond traditional SMT circuit boards or flexible circuits

Adhesion is particularly a challenge between rigid die and the stretching or moving fabric in wearable applications. ZTACH® ACE is applied in a single stenciling step, followed by magnetizing and curing. The material is applied across the entire footprint of the component to provide both interconnection and structural bonding to the electrical circuitry on the fabric. ZTACH® ACE stabilizes the interconnect sites – the Z-axis columns of aligned particles, held in place by the epoxy resin, allow for flexing of the surrounding textile while maintaining electrical connection.

Despite notable progress being made in e-Textiles, significant challenges remain relative to functionality, reliability, scalability, and cost. Robust interconnects have been repeatedly noted as a primary challenge in both conformal Flexible Hybrid Electronics and Stretchable e-Textiles. SunRay Scientific’s innovative z-axis conductive adhesive is compatible with integrating into an SMT line with reduced steps, no pressure, and at low temperature. ZTACH® ACE, with minimal design requirements, is easily incorporated into current or new product designs while supporting miniaturization and light weighting of electronic assemblies and wearable e-textiles. ZTACH® ACE has been shown to be a reliable interconnect solution over conventional methods and has demonstrated scalable production of wearable electronics.