Buildings in the US account for 40% of the country’s energy usage. To many, that statistic simply reflects how things are. That was true for the Science Museum of Minnesota’s team, too, until an intrepid mechanical engineer contextualized the museum’s own energy usage in a new way: Why are you throwing away energy that could be used to heat the building?

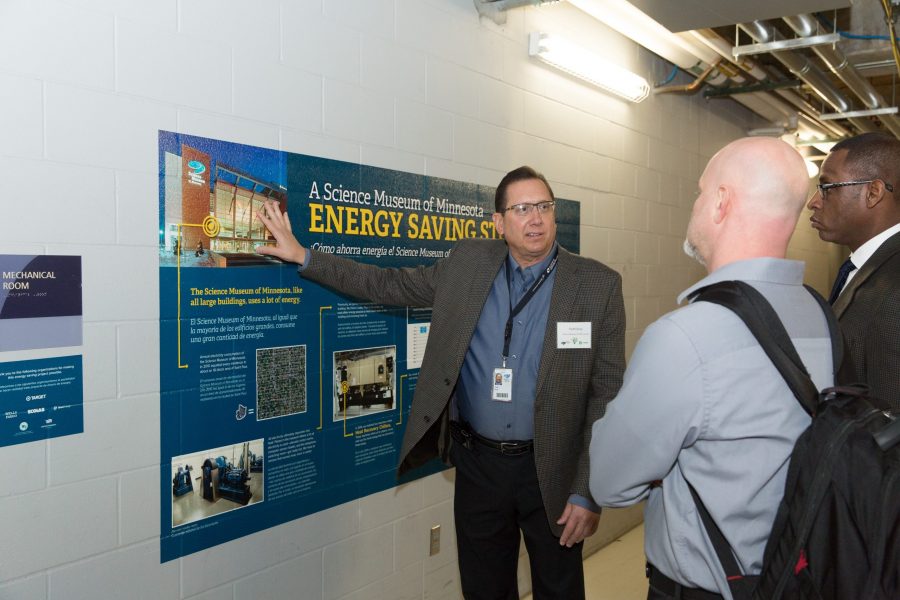

A large wall graphic presents tour goers with an overview of the Science Museum’s entire advanced heat recovery system before they experience its individual components.

Hundreds of architects, engineers, developers, building owners and operators, and policymakers have taken advantage of behind-the-scenes tours of the Science Museum’s advanced heat recovery system in recent years.

There was only one real reason: “Because no one had ever put it to us like that before,” says Patrick Hamilton, Director of Global Change Initiatives at SMM. Anything that uses electricity generates heat, and the larger it is—a computer server, a telephone-switching room, an elevator—the more heat it generates. Historically, the standard operating procedure for American buildings has been to treat this electronics-generated heat as waste and pump it out of the building. The Science Museum did something different.

“We committed to an overhaul of our energy system, one centered around two Trane heat-recovery chillers, which simply put, move energy from one place to another within the building,” Patrick says. Like most buildings of its size, the Science Museum has simultaneous heating and cooling demands, even in wintertime. The heat-recovery chillers remove heat—which was previously being pumped out as waste—from areas with its building where it is in excess and reroutes it to other parts of the building that require it. In the wintertime, the heat recovered by the heat recovery chillers is used to temper the fresh but cold air brought in from the outside before being circulated throughout the building.

Just a Quick Note:

InnovationsOfTheWorld.com has partnered with Trade License Zone (TLZ) to support global innovators looking to expand internationally. Take advantage of the UAE’s Free Zones—enjoy streamlined setup, low corporate taxes, and a strategic gateway to the Middle East and beyond.

Get Your UAE Free Zone License Fast & Easy!

Fresh outside air being constantly pulled into the Science Museum by the building’s air handling units fl ows through a fl oor-to-ceiling fi lter before passing through a heat exchanger immediately behind it.

Hot liquid produced by the heat recovery chillers trickles down through the fl oor-to-ceiling heat exchanger, transferring heat energy to incoming fresh air before being distributed throughout the museum by the air handling units.

The chillers’ installation was completed in 2014, and the results have been remarkable. “One February morning in 2017, I got an email from one of our engineers, and it contained a screenshot of our energy consumption. He’d written, ‘It’s 4°F outside right now, and we’re buying zero hot water from District Energy,’” Patrick recalls. Other figures surrounding SMM’s energy savings are more fun for him to let the uninitiated guess at:

- By what percentage has SMM reduced its yearly energy usage? Anywhere from 60–75%, depending on the severity of the winter.

- By how much has SMM reduced its carbon pollution? One third. How long did it take SMM to recoup its initial $900,000 investment? 3 years.

- What is the museum’s average annual savings on heating and cooling? $300,000.

“We’re seeing this very beneficial flywheel where investment in energy efficiency allows us to reduce our footprint and to save money that we can instead invest into the museum itself and into further energy savings,” Patrick says. Sight unseen, the museum’s heat-recovery system sounds almost too good to believe—so the museum offers behind-the-scenes tours. Hundreds of architects, engineers, building owners and operators, developers—and even some potential Trane clients—have come to see the heat-recovery system in action. The museum has installed interpretation in many of the spaces that the system tours traverse, including the building’s fresh-air plenum.

One of the two heat recovery chillers that removes heat from areas within the Science Museum where it builds up due to high electricity use and then steps up this heat energy and transfers it to a heat exchanger.

“When you walk into it, you’re actually walking into whatever the weather is outside. If it’s snowing outside, it’s snowing in this giant concrete box in the heart of the museum that you’re standing in,” Patrick says. “Then when you walk into the plenum on the other side of the heat exchanger, you can feel how dramatically the fresh but cold outdoor air is warmed before air handling units distribute it throughout the museum.” The investment that the Science Museum has made into its energy efficiency is a signifi cant step toward the institution’s goal of carbon neutrality, which Mayor Melvin Carter has challenged the entire City of Saint Paul to achieve by 2050.

To that end, the museum is looking into other energy innovations, including perhaps ground-coupled heating and cooling (as exemplified by Darcy Solutions, a startup out of the University of Minnesota). The Science Museum has also partnered with the City of Saint Paul Public Library’s Read Brave 2020 program: Our climate crisis. Through a suite of books for every age, short videos, and events, the museum and the library are empowering both young and old to understand and deal effectively with climate change.

Whatever its next project, the museum is committed to remaining a beacon for dynamic and responsible energy sourcing. “We’re just one building,” Patrick says. “But imagine the economic and environmental benefits if other buildings—if every building—committed to reducing their carbon footprint.” The Science Museum of Minnesota has proven that it’s not only possible, it’s amazing.