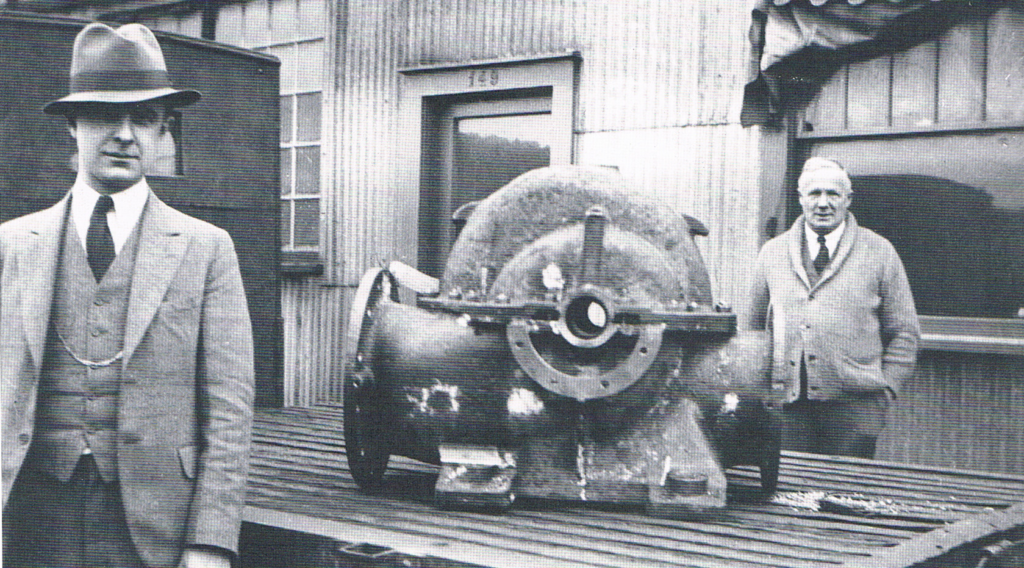

Reliance Foundry has deep roots as a maker, designer, and supplier of architectural site furnishings, metal castings, and industrial wheels—but just because they are an old company doesn’t mean they’re laggards behind a changing world.

Founded in 1925 in Vancouver, BC, Reliance grew to become the area’s largest working foundry, supplying metal parts to municipalities and the mining and forestry industries. Many of these castings have stood the test of time, such as the gates at the Cleveland Dam, expansion joints on the Oak Street bridge, and the lamp standards in Gastown.

Early in the company’s history, Reliance created a one-ton electric melting furnace, allowing a higher consistent throughput long before this capacity became standard. Reliance was also the only metal foundry west of Ontario that produced malleable iron, a form of cast iron made less brittle through a long-annealing heat treatment.

Later, Reliance was one of the first foundries in BC’s Lower Mainland to cast manganese steel, an alloy offering exceptional mechanical properties for the mining industry. Eventually, in the 1960s, the foundry pivoted away from malleable into ductile iron, which has a microstructure that still allows for ductility but without the expensive and technical heat treatment process.

Just a Quick Note:

InnovationsOfTheWorld.com has partnered with Trade License Zone (TLZ) to support global innovators looking to expand internationally. Take advantage of the UAE’s Free Zones—enjoy streamlined setup, low corporate taxes, and a strategic gateway to the Middle East and beyond.

Get Your UAE Free Zone License Fast & Easy!

A Sunset Industry

Though supply and economic challenges continued to be met through ceaseless innovation, eventually the North American foundry industry had to face that it could not compete with the increasing globalization. At the height of the industrial age, there were more than 140 foundries throughout BC; today, there are less than 10.

Fortunately for Reliance, the new owners had a lifetime of understanding of the intricacies of industrial metalwork and client needs, but also a modern outlook on business practices and trends. Brent Done, interested in the newly-available internet, created a company website for fun—one of the first for the foundry industry—and was surprised to find an influx of inquiries about products from customers across North America. Brad Done took his metal knowledge to Asia, finding overseas foundries that met his high-quality casting standards, that could cast Reliance’s designs at prices that would keep the company competitive.

In 2002, Reliance Foundry’s local foundry poured its final metal casting, and became a contract manufacturer of metal products, drawing in new customers internationally via its website.

A Digital Future

As Reliance continues to provide custom and industrial metal castings alongside architectural site furnishings across North America, they continue to broaden their offerings with innovative products. Under new leadership again, Shane Kramps and Pritesh Desai began seeing crossover opportunities with many of their municipal and large facility clients, and they began to work on a suite of IoT digital products that could be integrated with their current products or function alone. This new Citysage division offers a diverse range of sensors: from level monitoring and pickup route planning for waste and recycling bins, to noise limit violation detection around construction sites, and others.

Citysage has quickly taken on a life of its own. With a rapidly expanding suite of products, now also including water level monitoring (both underground and in open-water areas), loitering detection, and more, Citysage saw and met the need for a comprehensive dashboard: one place that municipal and facility staff could go to quickly get an overview of their purview, along with alerts for issues requiring immediate attention.

Innovation has long been an indispensable part of Reliance’s business success story, but it comes hand in hand with respect for long legacy and the extensive knowledge of its people. As Reliance approaches their first century as a company, they look toward a bright future for the next hundred years—a future of making places people want to be.