Hands-on experience is the key to create and open new opportunities that others don’t see and are not willing to seize the moment. Mixing, dosing and separation technologies are crucial for all worldwide industries. These industries are: water, wastewater, energy, oil, gas, pharma, mining, marine power; as well as, food and beverage industries such as beer, wine, rum distilleries, poultry, cosmetics, and dairy products.

100-year-old mixing technologies are still used today in all industrial, food, beverage and municipal water and wastewater facilities around the world. The resulting downsides have been: high energy and operational costs, space consuming and exponential dollar initial investment costs. Since the 1960s the mixing technology market has been forgotten…until 2020.

Back in 2017 I created and developed a new category of industrial mixing technology capable of mixing, dose and even separating all types of liquids, polymers, oils, chemicals, and dry chemicals. A technology that reduces 98% electric consumption; a technology that can be either electric, non-electric, pneumatic, hydraulic, or even solar powered. A technology that eliminated the use of external dosing pumps in mixing machinery. Today this Patented technology is reducing energy and chemical consumption, saving our customers more than 75% in chemicals, electricity and operational costs.

I’m a process engineer with 25 years of history working in the environmental industry. Since 1998 I have traveled the world while working for Suez Environment, a French company. In 2007 I decided to move back to Puerto Rico, born and raised, to start my 1st environmental service company Primavera Zero, Corp., and with the creation and continuous R&D of my 2017 new mixing technology I founded PolyGhost Technologies, LLC. in 2019. In September 2020 I received my 1st mixing technology patent from the United States Patent and Trademark Office.

The cool part of our technology is that we exponentially unlock an unseen industrial category capable of operating in multiple industrial global markets. From liquid chemicals inline blending, dry powder mixing, dosing pumps, inline mixers, automatic self cleaning strainers, liquid-liquid separators, liquid-solid separators, inline sludge thickeners, and the environmental remediation market. PolyGhost Global Market Size exceeds $100+ Billion dollars.

These are all the industries that PolyGhost is able to impact:

- Biotech and Pharmaceuticals

- Marine and Transportation

- Biotechnology

- Marine

- Pharmaceutical production

- Engine and transport

- Energy

- Mining, Minerals and Pigment

- Biofuels

- Base Minerals and Mining

- Heat and Power

- Coal Beneficiation

- Crude oil refinery

- Precious Minerals and Mining

- Engine power

- Pulp and Paper

- Nuclear power

- Paper production

- Oil and Gas

- Pulp production

- Machinery and Manufacturing

- Water and Waste treatment

- Construction machinery

- Fluid power

- Municipal wastewater treatment

- Environmental Remediation

- Industrial water and wastewater treatment

- Marine Conservation

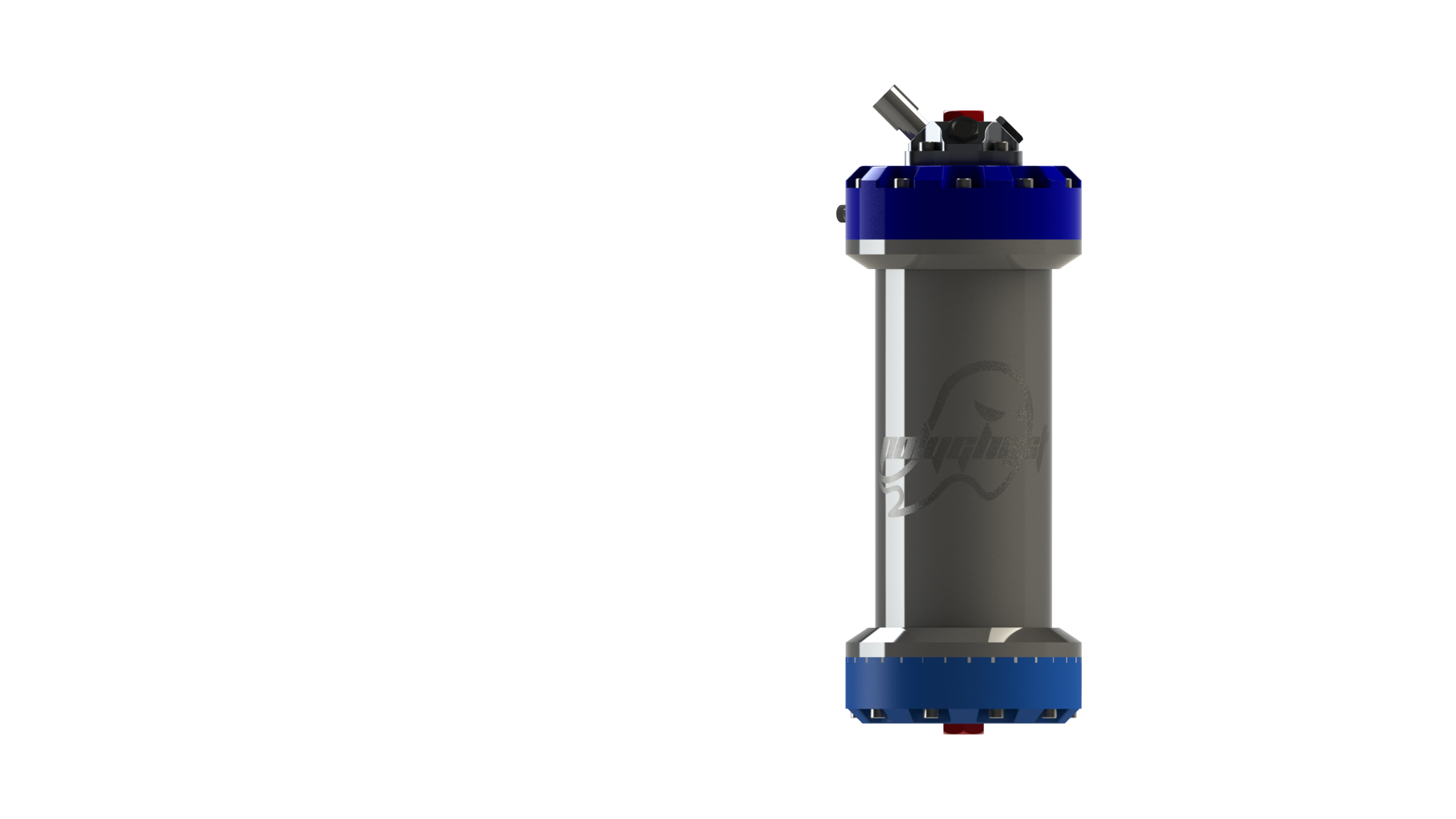

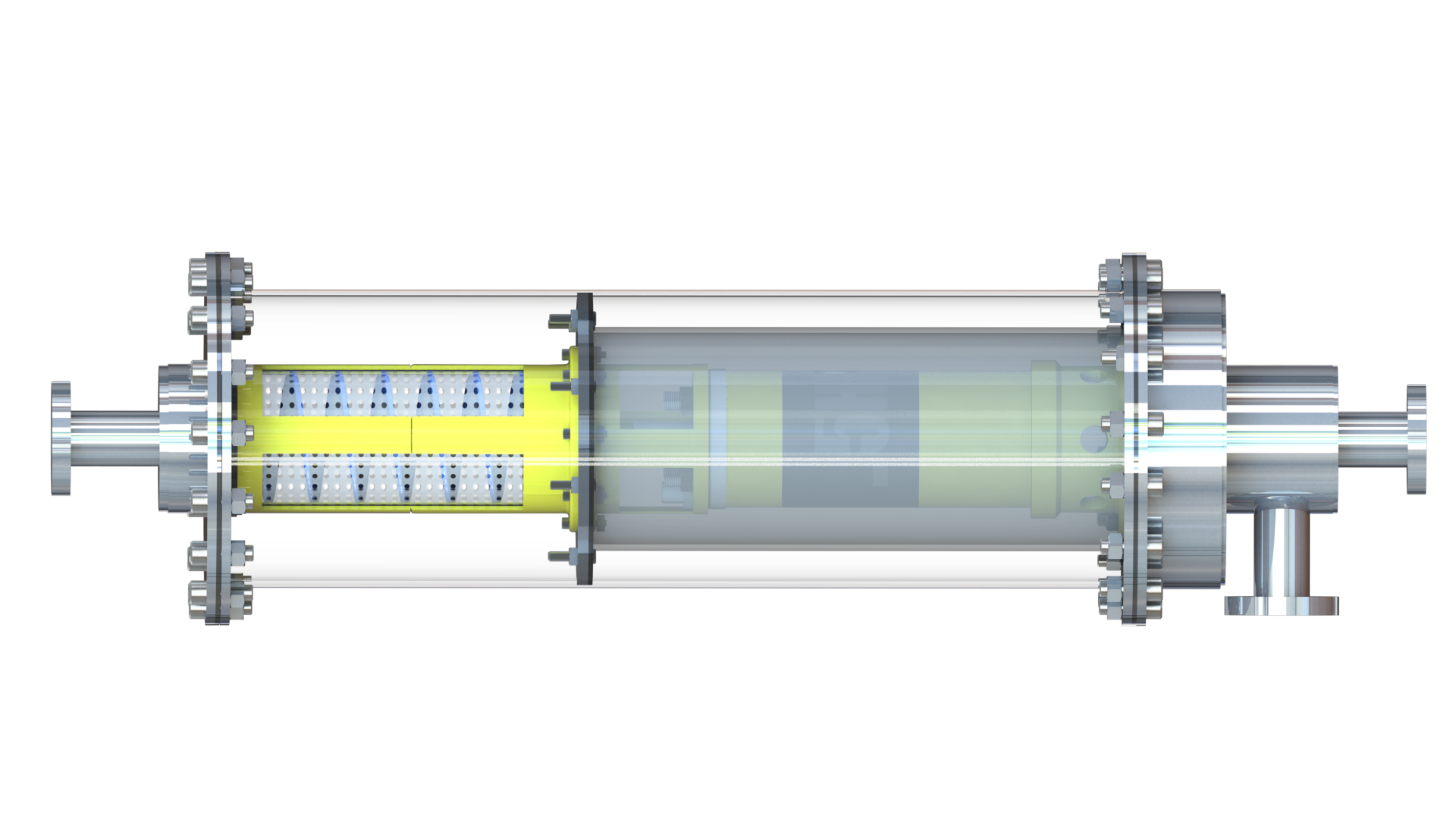

The PolyGhost Mixing Chamber:

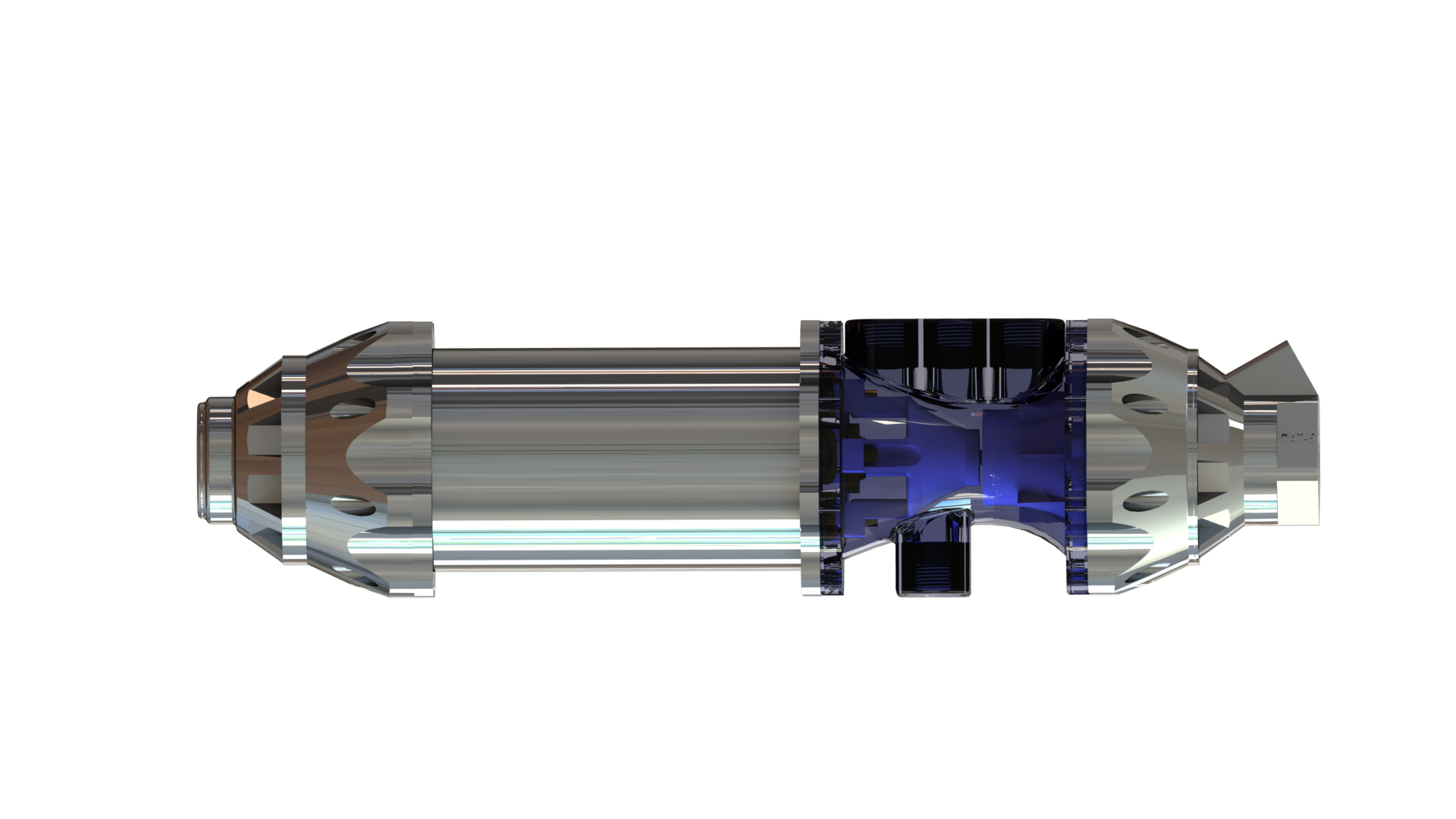

PolyGhost’s 2020 USPTO patent continuous blending chambers efficiently blend chemicals, nutrients, additives, formulas, and liquid polymers for food and beverage and industrial facilities. Inside our mixing chamber there is an initial mixing reaction zone (The Reactor – 1st mixing zone) with multiple inlets to facilitate the mix of different and multiple types of liquid products simultaneously. A submersible motor that is located inside a multistage mixing cup with orifices (The Cup – 3rd mixing zone) drives an impeller (The Impeller – 2nd mixing zone). A multi disc baffle cup with numerous orifices surrounds the motor controlling the retention time and instantaneous aging of the created solution (The Multi Disc Cup – 3rd mixing zone). A final polishing of the created solution takes place at the end of the chamber. This polishing cup with many orifices acts all together as a final mix and as a motor holder (The Polishing Cup – 4th and final mixing zone).

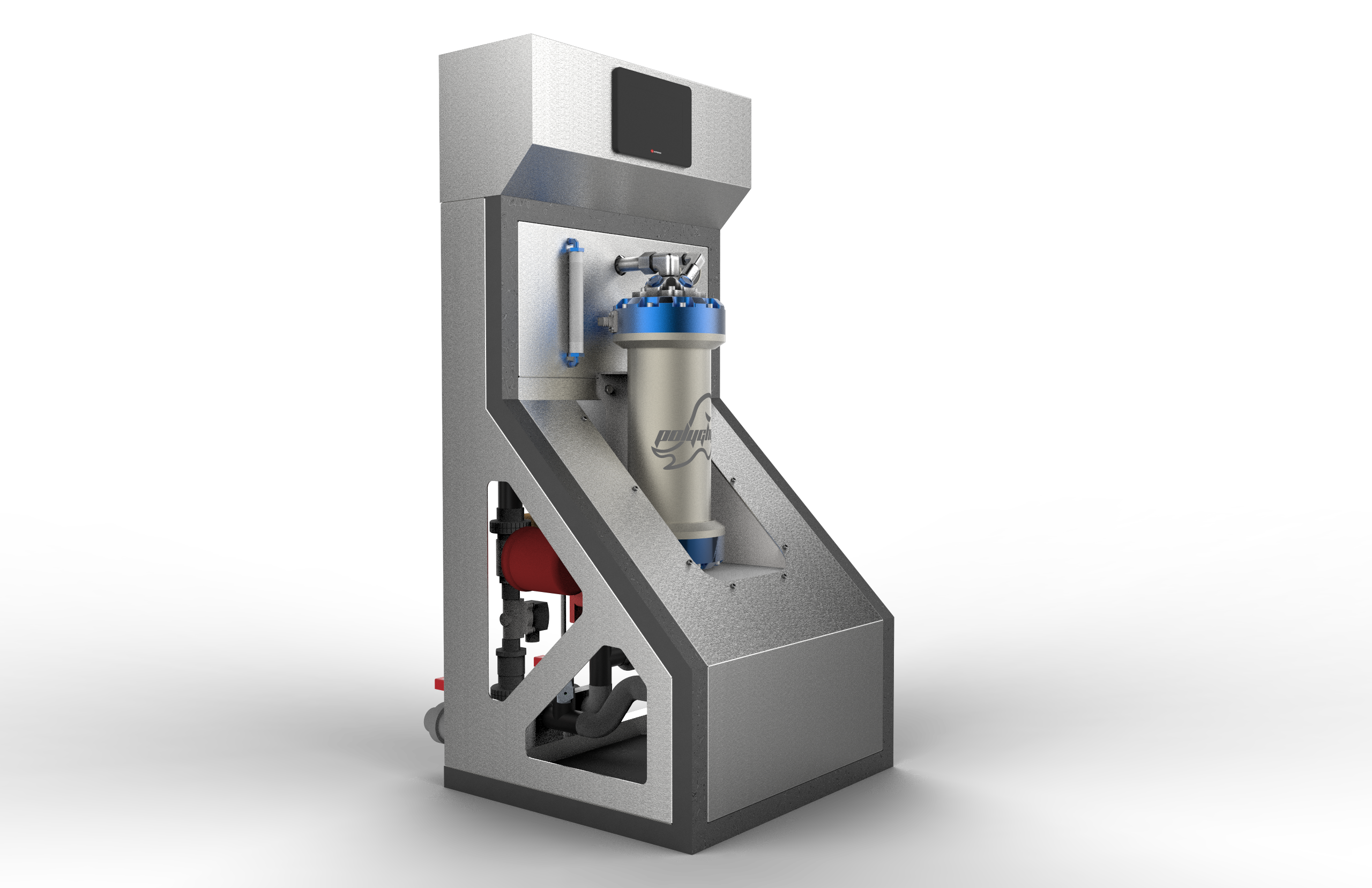

GHOST SKIDS Liquid Polymer Activation Skids:

The Ghost Skid is a versatile liquid polymer activation system that integrates our 2020 USPTO patented mixing technology with the use of external dosing pumps to create a perfect neat polymer activation skid. GhostSkids are neat polymer activation skids that are part of dewatering applications worldwide. GhostSkids are electric powered.

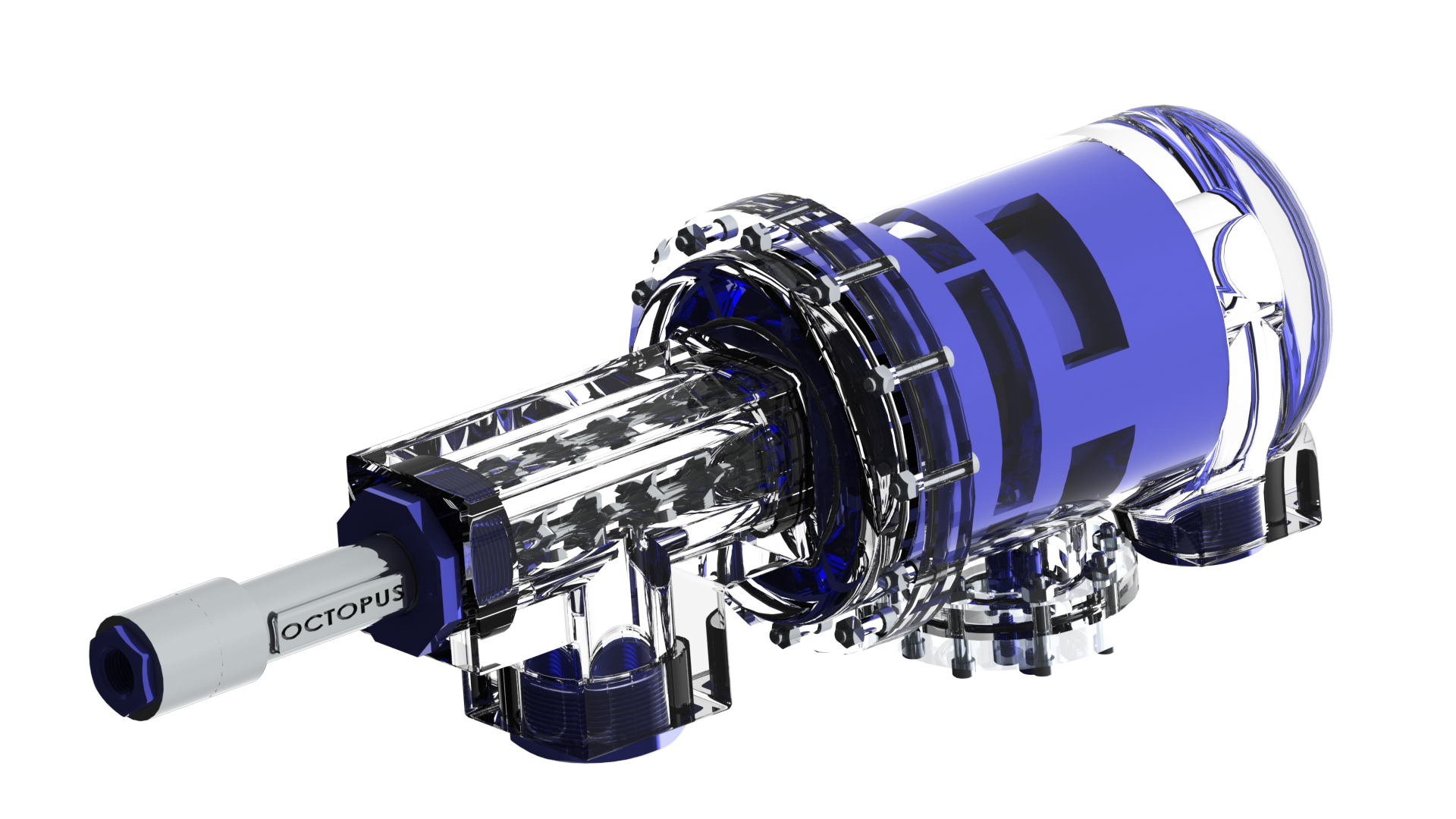

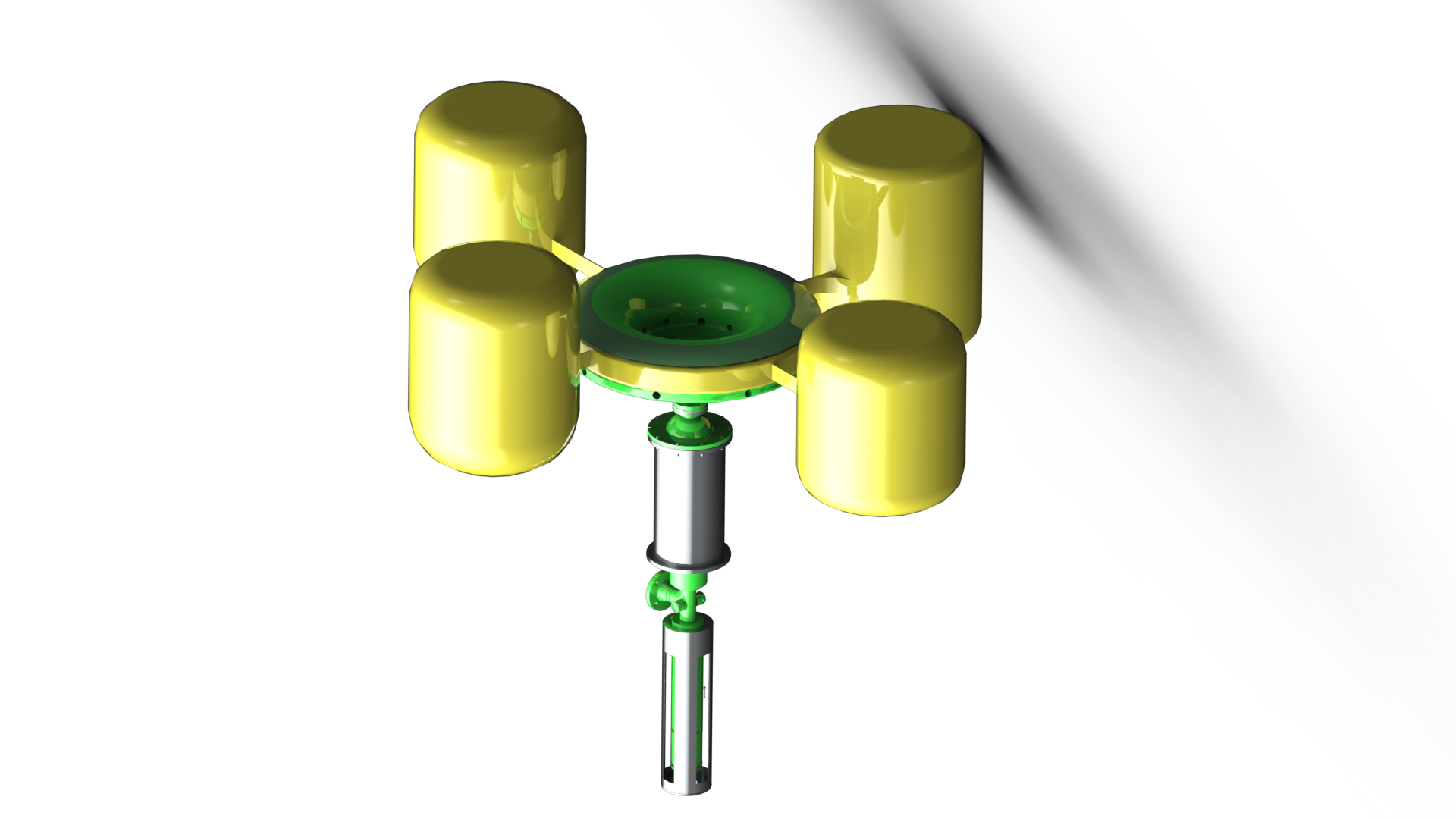

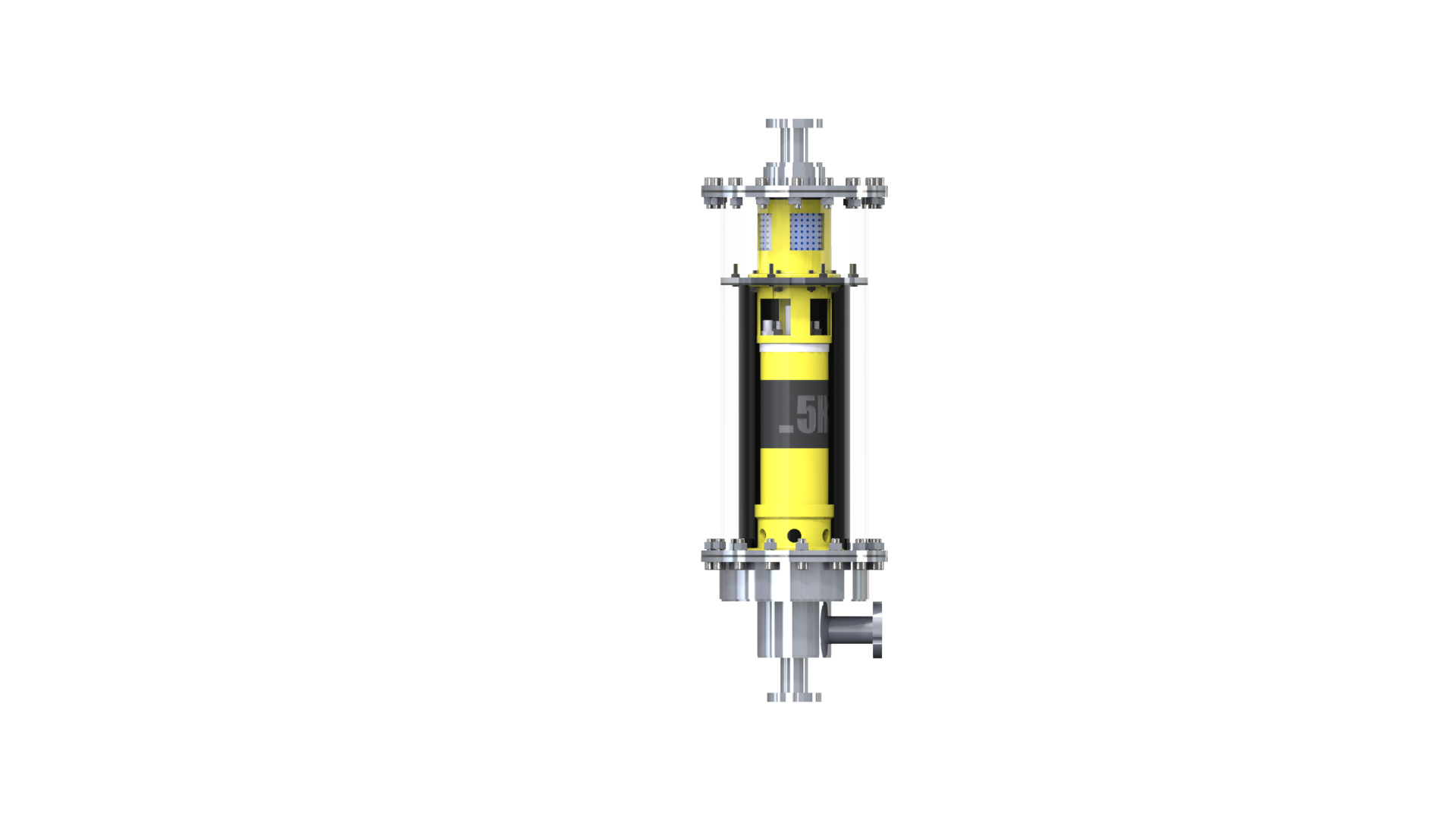

OCTOPUS Dosi-Mix Pumps:

The OCTOPUS Dosi-Mix Pumps are revolutionary. The OCTOPUS is a hybrid of a mixer and a dosing pump. Octopus Dosi-Mix pumps can efficiently dose and mix at once, chemicals, liquid polymers and more using only compressed air. The Octopus is the 1st NON-ELECTRIC DosiMix pump. Just plug air and play… The Octopus is the 1st pneumatic DosiMix All-in-One Pump that integrates:

- Blending Chamber

- Submersible pneumatic motor

- Aging Cup

- Mixing Cup

- Mixing Reactor

- Mixers

- Progressive cavity Dosing pump

The OCTOPUS Dosi-Mix Pump are the All-in-One mixing dosing chambers. It is the dosing pump… it is the mixer. The dosing pump is driven with the same submersible non electric motor that drives the mixer. This uniqueness takes us to another level not seen before. We eliminated 100% the use of external dosing pumps. The Octopus offers several tentacles or liquid product inlets to ease the preparation of various types of liquids, chemicals, polymers, oils, beverages, and alcoholic blends. A single Octopus can incorporate up to 4 dosing pumps and 4 liquid product inlets or outlets. Numerous configurations, dosing and flow capacities are available.

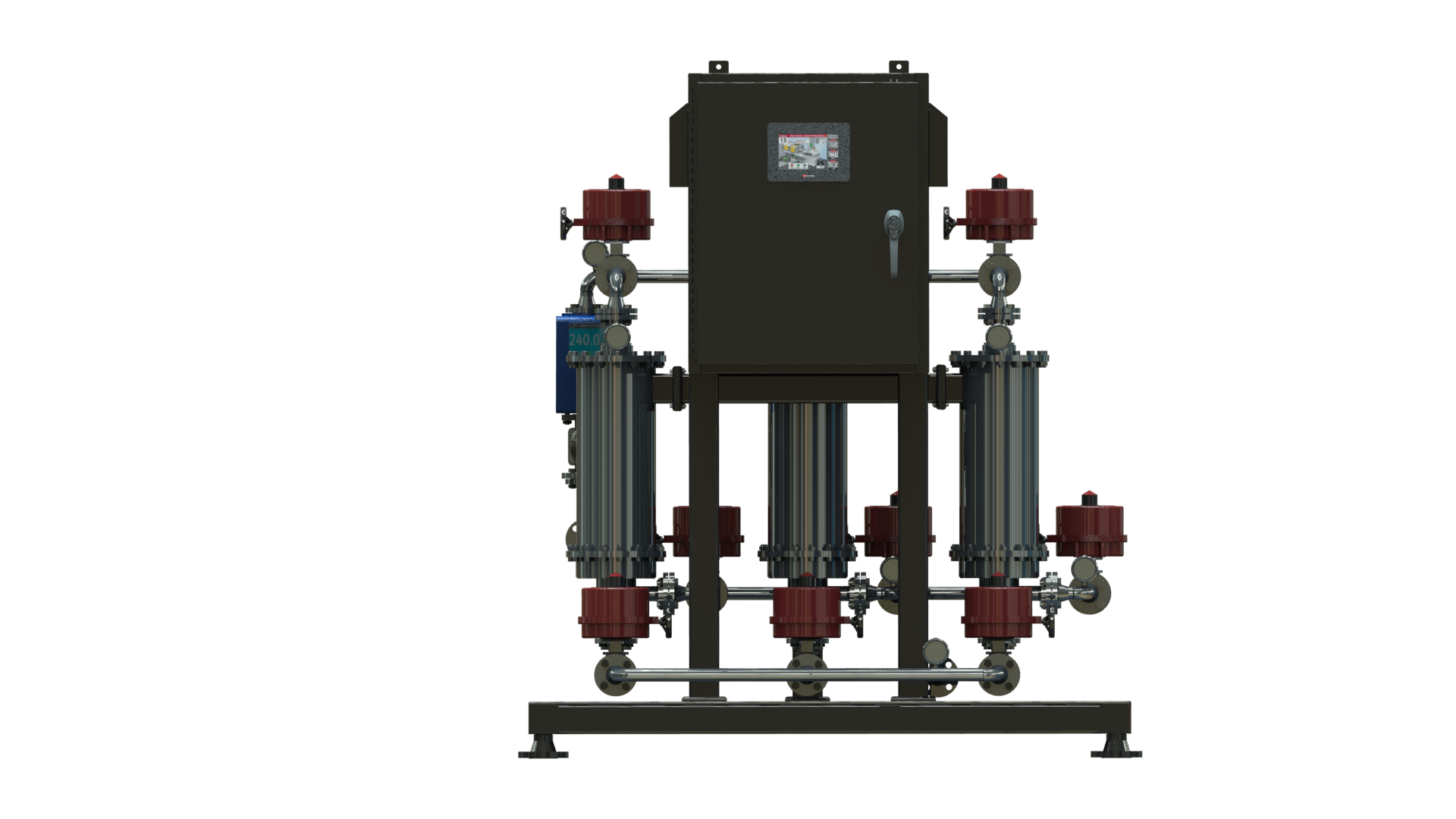

OCTOPUS Non Electric Dosi-Mix Skids:

No electricity, no vfds, no contactors, no breakers, no plc’s, no electrical components, no control panels, no electric external dosing pumps, no polymer check valves… The All-in-one Non-Electric Octopus Pneumatic Dosimix Skids are here to stay. Just plug air and play! As sole owner of the revolutionary Non-Electric OCTOPUS Dosi-Mix pump technology, PolyGhost positively distances itself from the competition. In the world of liquid polymer activation and liquid chemical blending the use of an external mixer, dosing pump and motor has been the norm for almost 100 years. These components operate together to create a blend. Costs rise when the need of different brands are purchased to assemble one skid. The breakthrough PolyGhost achieved creating the OCTOPUS, has deleted from the industrial equation the use of external electric dosing pumps, electrical items, and control panels in polymer or chemical activation feed skids.

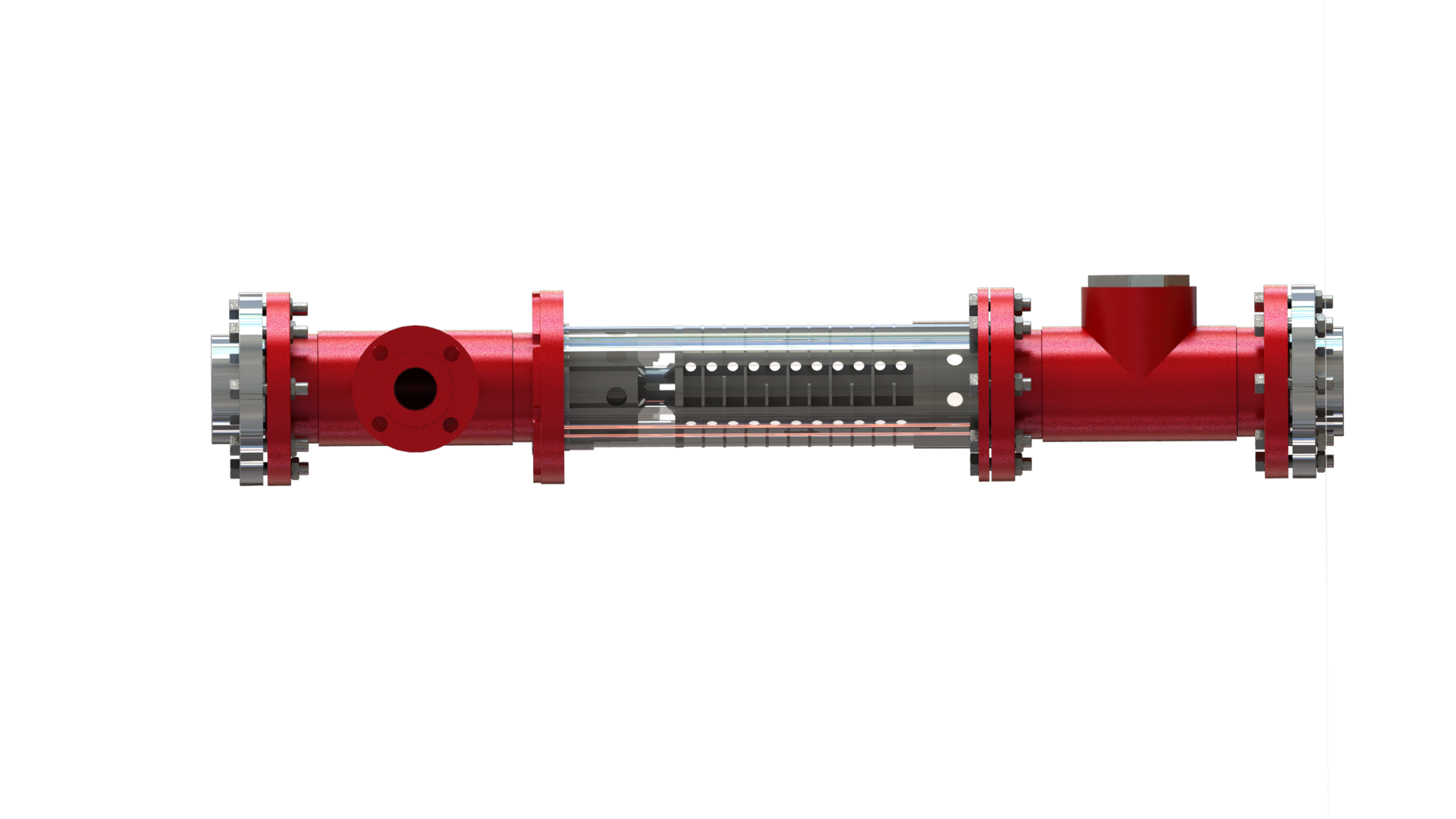

CAT-5 Dry powder mixing technology:

The CAT-5 Dry Powder Mixing Technology is an innovative industrial inline powder dissolution unit that instantaneously and efficiently disperses powders mixing them with liquids into a homogeneous blend. The CAT-5 inline mixers are units designed to operate at high flows and under rough-tough environments like the oil and gas, mining, and fracking industries. The CAT-5 integrates JET Propulsion Technology inside our mixing chamber. The CAT-5 mixers can be provided as standalone units or mounted in a complete mixing skid with control panel and accessories.

GHOST INLINE MIXERS:

Ghost Inline Mixers operate similar to static inline mixers. Static mixers have no moving parts. However, what differentiates us from the existing competitors, is that we integrate a mixer that is driven with our submersible electric motors and additional static orifice cups with integrated multiple static mixing baffles and reaction zones for solution retention time, aging and final polishing. We can custom develop inline mixers from 2” up to 16” pipe size diameters. We can use submersible electric motors from 0.5 HP up to 100 HP. No limits.

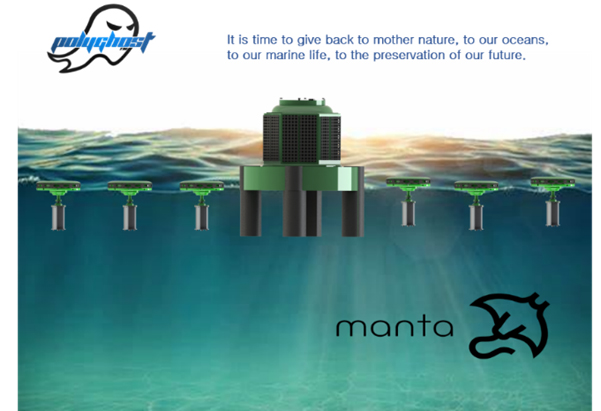

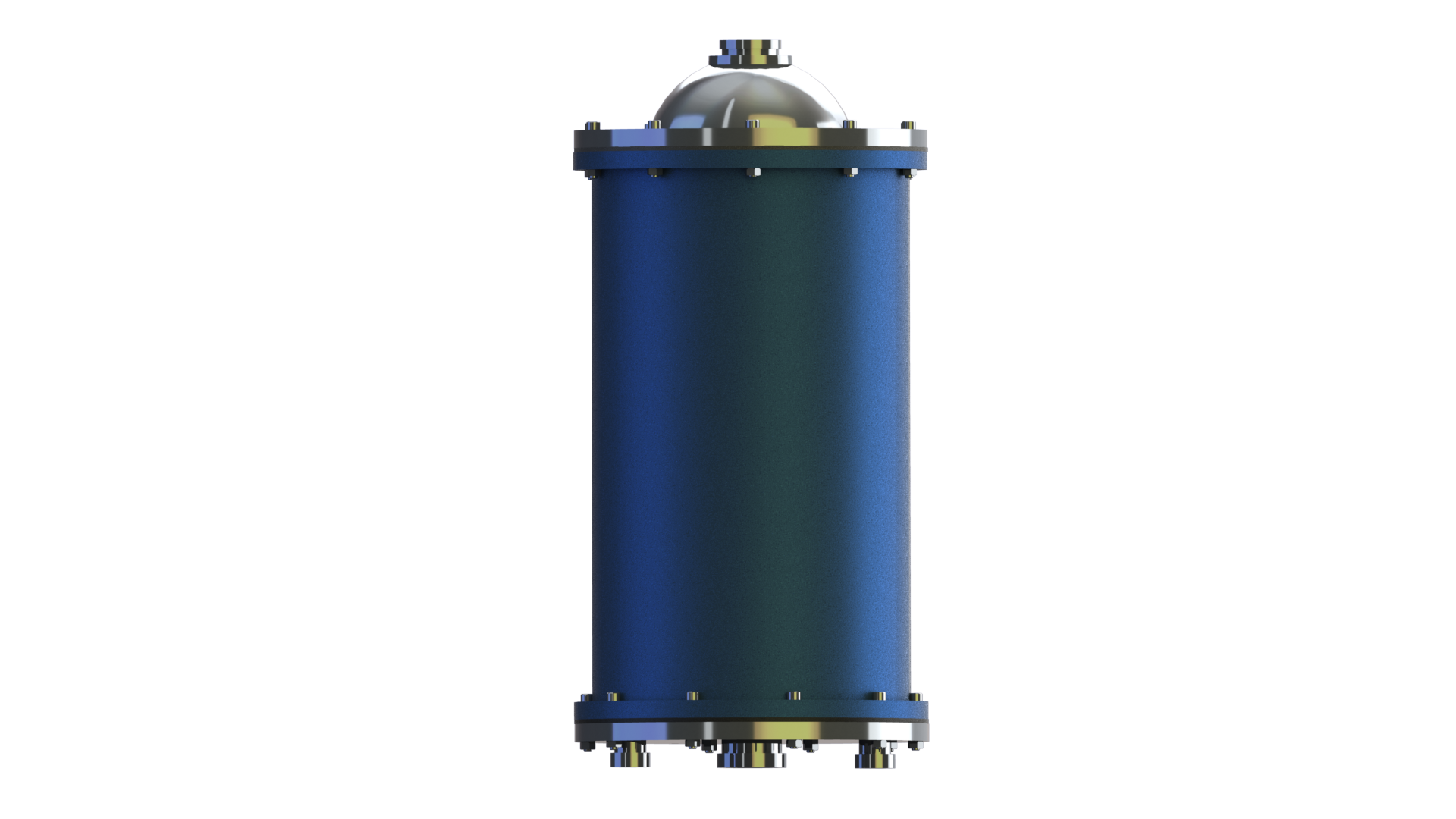

MANTA Oil Spill Remediation Technology:

This technology is the one I like the most! And it has a true story behind it… On a Saturday morning, back in 2019, my daughter and I noticed a strange smell coming out from our beach spot. The sand, the water and marine life were covered in oil. Accidentally thousands of gallons of hydraulic fluid were dumped into our beach. My daughter asked me, “Are our fish going to survive? Can we do something? my answer was “Yes, they will survive, and we will do something…” The PolyGhost Manta Separator is the 1st oceanic solar powered oil spill remediation technology. The 1st floating oil/water centrifugal separation technology. The 1st inline oil/water separation technology using submersible motors inside a separation chamber that are in direct contact with the separated liquids. Our blending chamber is converted into a separation chamber. Inside this chamber you will find a highspeed solar powered submersible motor. Our speed range can go from 2,000 RPMs up to 12,000 RPMs driving at the same time an internal high speed disc separator with a series of oil and water distribution chambers. This new remediation technology can be used in small size and large-scale size oil spills. It is an unprecedented technology under PolyGhost’s USPTO Patented Technologies. It is time to give back to Mother Nature, to our oceans, to our marine life, to the preservation of our future.

Ghost Automatic Self-Cleaning Filters skids:

PolyGhost Automatic Self-Cleaning Filters are systems that automatically separates and remove solids from liquids streams.

Ghost Inline Sludge Thickeners:

Ghost Inline Sludge Thickeners are compact and versatile systems that increase sludge solids concentration. The total sludge volume is reduced but the sludge still behaves like a liquid instead of a solid.

Ghost Oil/Water Separators:

Ghost Oil/Water Separators are the 1st inline oil/water separation technology using submersible motors inside a separation chamber that are in direct contact with the separated liquids. Our blending chamber is converted into an oil and water separation chamber. Inside this chamber you will find a high-speed solar powered submersible motor. Our speed range can go from 2,000 RPMs up to 12,000 RPMs driving at the same time an internal high speed disc separator with a series of oil and water distribution chambers.

Polyghost opened new ways to do things differently and effectively. Our new technologies are opening new doors to customize and optimize existing and future processes all around the world and we are just starting.