Marc is a passionate engineer who has been active for more than 40 years in first-of-a-kind product development from the first multi-media computers to DVD recorders to smartphone chipsets and EUV light sources for the newest chip making machines of ASML. Marc spent most of his international career in The Netherlands at the High Tech Campus in Eindhoven.

“The evolution of digital technology and the 0exponential complexity increase in the products that we use all the time, also affects production technologies deeply and requires close cooperation between many companies, each delivering their unique process technology and modules. At the same time Industry 4.0 and the innovation towards product personalization – up to production lot sizes of 1 – and product servitization – where the producer remains the owner of their products during their full lifetime – bringing about the need for more local production and maintenance.

To solve these extremely complex puzzles timeously, companies need to innovate and work together closely based on mutual trust. By sharing their problems and helping each other in solving the issues in an atmosphere of open innovation, working solutions can be created in the shortest possible timeframe and further improve continuously.

After having experienced this open innovation in research and development in practice at the HTC in Eindhoven, I was convinced that this was and is the way to go – also between engineering and manufacturing companies – to enable more and more local production.

Just a Quick Note:

InnovationsOfTheWorld.com has partnered with Trade License Zone (TLZ) to support global innovators looking to expand internationally. Take advantage of the UAE’s Free Zones—enjoy streamlined setup, low corporate taxes, and a strategic gateway to the Middle East and beyond.

Get Your UAE Free Zone License Fast & Easy!

Therefore I immediately accepted the challenge to build an Open Manufacturing Campus OMC at Turnhout and a related ecosystem on and around the premises of Philips Lighting (now Signify), while their activity would gradually decline in parallel.

After renovating two large production halls, opened in 2015, more than 20 companies work together at OMC around themes like 3D printing and Renewable energy systems, as you can read on the following pages. Time to start the construction of a new space to keep innovation going at an even larger scale, next to the highway, half an hour’s drive from both Antwerp and Eindhoven and always open to welcome visitors!”

3D PRINTING @ OMC

LUXEXCEL

The pioneer in 3D printed lenses, owns unique UV curing inkjet technology for printing ophthalmic lenses. By using this technology new smart glasses can be developed with embedded filters, sensors, displays and waveguides integrated in the lens.

We provide the best of both worlds: prescription powers and smart tech, in a single eyewear lens that forms the basis for the new generation of personalized and fashionable AR glasses.

Recently we received the prestigious PRISM award at the SPIE Photonics conference in the augmented reality category, the technical Oscar for our innovation.

SIGNIFY 3D PRINTING

Mass-market, on-demand tailored luminaires that can be recycled. Sounds too good to be true? It’s not.

Signify enables customers to custom-design or tailor their luminaires. We then 3D print and deliver a quality product, fast. Our service saves on time, energy, waste in manufacturing, packaging and transportation. 3D printing paves the way for more innovative designs with more complex shapes and colors. These are available digitally for on-demand production and stored to allow easy modification and adaptation.

What’s more, all our 3D printed Philips luminaires are recyclable, specifically designed for a Circular Economy.

Our factory at OMC is one of the biggest 3D printing facilities in Europe.

SADECHAF

Adhesive technology at the highest level: Sadechaf develops and manufactures high tech adhesives and resins and we deliver them to production facilities worldwide. Our products are used in a wide variety of applications, ranging from 3D stereolithography to micro dots in optical sensors.

“Finding a perfect adhesive for your application in meetings from Technician to Technician, and this for a competitive price, this is our challenge every day”.

40 years of expertise in UV and UV LED Curing Technology:

Sadechaf also selects, installs and maintains for its customers the right UV system suited to their needs. Our extensive maintenance services and range of lamps and spare parts of the most renowned UV manufacturers secure the efficiency and continuity of your operation.

Since 2018 a proud member of OMC: Being surrounded by other companies who are speaking the same language enhances the individual capabilities of the OMC participants.

ABSOLEM

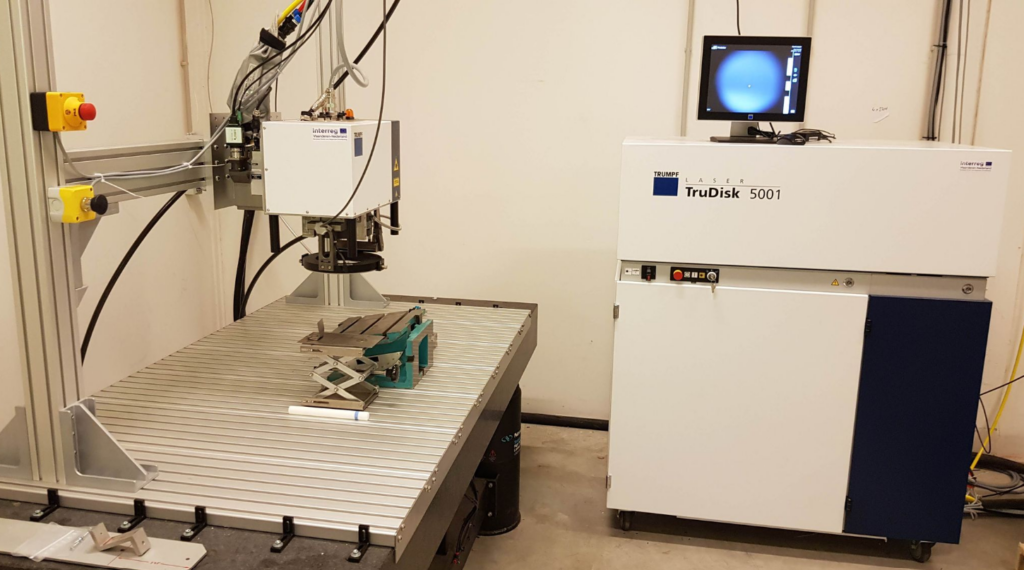

As a high-tech engineering company Absolem thrives in the OMC ecosystem. With our expertise in R&D, engineering, prototyping and machine building we quickly were able to partner with several other companies based at OMC.

Just a few examples: our laserlab creates leak test samples for eyetec, our conceptual designers work with Luxexcel to develop prototypes of new machines and our engineering center creates parts and small units for Classified Cycling. The partnership with Signify was a given, as they represent the roots of Absolem. We have done several large projects together and are their preferred partner for engineering consultancy.

Other companies like Cartamundi (machine development) and Ergotrics (marking) have become regular visitors at our engineering center as well.

We are glad we can help invent, develop, build and innovate their products or production environments. And at the same time they continuously help us question and innovate our own technologies and processes. This form of innovation and co-creation certainly would not have been possible outside of the OMC ecosystem.

ENERGY @ OMC

WATERSTOFNET

WaterstofNet is a knowledge and collaboration platform, initiating and realizing sustainable hydrogen projects in Flanders and the Netherlands. It unites the hydrogen industry in Benelux, with the center of gravity in Flanders, and coordinates a regional hydrogen ecosystem (Waterstof Industrie Cluster) of over 120 companies.

WaterstofNet is also coordinator/ partner in over 20 hydrogen projects on various topics such as transport, import, ports, hydrogen backbone, built environment, research programmes, etc… This results in a lot of hands on experience in the field. Moreover WaterstofNet is the preferred partner of the Flemish government and is working closely together with the governments in Belgium, Netherlands, and Benelux. And is directly connected with the major authorities on hydrogen in Europe.

WaterstofNet also draws up roadmaps and hydrogen studies for companies. It disseminates knowledge about hydrogen by organizing a ‘Hydrogen Academy’ and dedicated workshops and conferences.

SOLENCO POWER

ENDLESS RENEWABLE ENERGY

Solenco Power NV is a fast growing Belgian SME innovator in the field of cleantech and specializes in hydrogen energy storage systems for residential, commercial and industrial installations.

Founded in 2015 by Dr. Hugo Vandenborre, a well-recognized hydrogen pioneer, and with a team with +50 years of experience in the hydrogen sector, Solenco Power is committed to the decarbonization of the energy sector.

Two products have been tested in the field and are now ready for commercial roll out: Powerbox® and Powerhub®. Both are based on a patented reversible fuel cell concept, so that renewable energy from solar or wind can be stored for days, weeks or months and later on be used for electricity production and heat.

Renewable energy storage based on hydrogen becomes a service to balance or compensate the mismatch between periods of generation and load.

DEKIMO

Dekimo is a service provider in electronics, mechatronics and software, employing more than 400 engineers in 18 offices in Europe. The Dekimo Turnhout office is located on the Open Manufacturing Campus after it acquired a former R&D branch of Leclanché SA and has now become Dekimo’s knowledge centre for battery systems. Dekimo is active in the development and manufacturing of a plethora of smart energy applications and has designed a new V2G (Vehicle-toGrid) charger, for example.

The charger is bidirectional, which means it can convert AC to DC power and back. The V2G charger is able to charge the battery of electric vehicles and, if needed, to also transfer power from the battery of the vehicle to the grid. Initiatives like the V2G charger help to improve the stability of the grid and make the grid smarter and more efficient.

MEDTECH @ OMC

ERGOTRICS

Is a Med-Tech company specialized in positioning and moving patients with compressed air. We design and produce inflatable medical devices, which allow for the optimal positioning of patients in hospitals, with special attention to ease of use and hygiene. By using compressed air instead of manual force, we want to provide better support for patients without the ergonomic burden for the healthcare worker in the Operating Room as well as the Intensive Care Unit.

Ergotrics has three published patents in Europe and two in the USA. Our products are sold in more than 18 countries worldwide and have won several prizes. Most recently, our Morphemat won the Business Innovation award in the prestigious Henry van de Velde competition. The Morphemat is an inflatable mat that helps caregivers in Intensive Care to tilt patients into alternating positions ergonomically and quickly. The Morphemat replaces the manpower of two to four nurses.