Since opening in 2017, the Makerspace at NJIT, a training-focused, rapid prototyping facility that is central to both the university’s hands-on learning mission and its growing relationship with New Jersey’s manufacturing community, has given rise to a number of ingenious devices used in research experiments, club team contests and startup ventures: inserts for hockey skates; a novel composting appliance created for a capstone project; a device to explore new energy sources deep below the Earth’s surface; and syringe prototypes for a health care startup that monitors the temperature of medications.

Adedotun Oyefeso, a forward on NJIT’s ice hockey team, sought to address his own problem – flat feet crimping his speed across the ice – by manufacturing an insert that lifted his heel slightly at the Makerspace. He ended up founding a startup to begin making it for amateur players without access to customized parts.

The senior capstone team, composed of four women engineers, envisioned their composting device as “an everyday appliance in the average house, like a microwave oven.” Homeowners would deposit their biodegradable waste into it from a sealable opening in the kitchen and later remove it for reuse from a second opening on the outside of the house. In the meantime, the decomposing waste could potentially generate enough energy to heat a room.

Just a Quick Note:

InnovationsOfTheWorld.com has partnered with Trade License Zone (TLZ) to support global innovators looking to expand internationally. Take advantage of the UAE’s Free Zones—enjoy streamlined setup, low corporate taxes, and a strategic gateway to the Middle East and beyond.

Get Your UAE Free Zone License Fast & Easy!

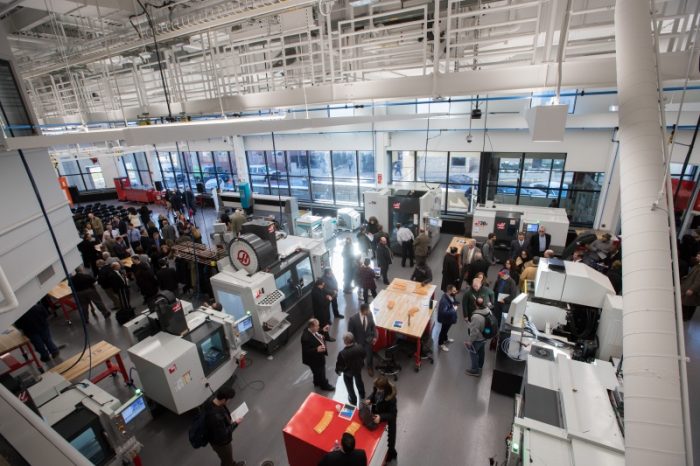

As the Makerspace’s scope rapidly expands, its space is poised to double to 21,000 square feet. The equipment inside ranges from small 3D printers to large industrial machines such as an additive metal 3D printer that uses powdered stainless steel to print parts, an optical scanner that effectively digitizes real-life objects, enabling reverse engineering, and a continuous fiber 3D printer that is capable of depositing strands of carbon fiber, fiberglass or Kevlar inside 3D-printed parts, to add considerable strength.

With funding from the National Science Foundation, Bruno Goncalves da Silva, an assistant professor of civil and environmental engineering, built a device in the Makerspace that will allow him to assess the possibility of tapping into vast stores of renewable, carbon-free energy within the Earth’s crust.

“So far, success in harnessing the Earth’s own heat has been mostly limited to tapping the boiling hot water that bubbles up with little prompting close to the surface,” Goncalves da Silva said. “The main challenge is to tap into deeper and less fractured hot rocks. This would make geothermal energy accessible in many more locations across the world. In order to achieve this goal, we need to fracture the rock in order to increase its permeability.”

But it is not only students and faculty who use the facility; it is also available to industrial partners to participate as mentors, trainers and instructors, to companies to collaborate with students and faculty members on research and development projects, and to employees to receive customized training tailored to their needs.

Businesses in the region, including companies in VentureLink, NJIT’s community-based business incubator, are already advancing their prototypes there. A startup called ThermaProx, with a device that will alert health care providers with heightened precision if a medication in transit has reached a temperature that may have compromised it, is a case in point. The device is a proxy sensor clipped to individual vials and syringes that mimics the temperature profile of the dose of vaccine or insulin on its final journey, rather than simply recording the ambient temperature in which it traveled.

“The rapid, inexpensive production of our syringe rod and syringe clip in the Makerspace allowed us to show prototypes to potential buyers and investors without long waits and large expense,” enthused Nathaniel Cooperman, a company co-founder.

The Makerspace is primarily, however, an integral part of NJIT’s curriculum and educational mission. The 10,000-square-foot expansion, now underway, will provide additional space for collaboration, including open areas to congregate, breakout rooms to brainstorm ideas, training rooms for instruction and additional CAD stations and equipment to design, build and test early prototypes.

“The expansion will allow users to bring ideas from concept to reality in one facility,” said Daniel Brateris, the director of experiential learning for Newark College of Engineering, who designed the Makerspace.