The Geel and De Nayer (Sint-Katelijne-Waver) campuses are part of the Faculty of Engineering Technology at KU Leuven. Here, high-quality education and research go hand-in-hand: not only do these campuses train passionate engineers, they also offer many opportunities for companies that want to innovate.

Our campuses play an active role in the Mechelen-Kempen region, and anchoring the two campuses in the surrounding socioeconomic fabric provides mutual benefits to all parties involved.

This relationship ensures that the research conducted here will not remain locked up within the university walls – the application-oriented dissemination of research results is part of our institution’s DNA. At the same time, numerous professionals from various fields work as teachers, trainers, evaluators or supervisors and enrich our programmes with their practical experience. In addition, companies propose topics for student projects, including master’s theses and innovation internships; in this way they give young, motivated engineering students the opportunity to get started with practical, real-world challenges. Innovation internships are the vehicle par excellence for innovating with limited resources.

This two-way traffic between education and research is characteristic of our academic programmes. Research feeds education with new insights and education trains students to become master of science in (bio) – engineering technology with a broad scientific background and an inquisitive, critical mindset – researchers, in short, who take nothing for granted. These problem solvers know how to get things done and, through their innovations, make our daily lives easier, safer and more efficient.

142 spin-offs

Scientific research undertaken in Geel and Sint-Katelijne-Waver formulates answers to major social challenges and helps to realise the Sustainable Development Goals, from clean water to sustainable industrialisation, from food security to responsible production patterns. To make this happen, our professors and researchers organise themselves in large, cross-campus research departments that are always closely intertwined with their industrial counterparts. The resulting ecosystems guarantee much-needed innovations in each of these areas.

Our university has a long tradition in the field of high-tech entrepreneurship. KU Leuven Research & Development (LRD), founded in 1972, was one of the first tech transfer offices in Europe. This success has its rewards: KU Leuven, named by Reuters as Europe’s most innovative university for several years in a row, now can boast 142 spin-off companies. Our campuses have already produced several success stories. In Mechelen, Inopsys focuses on water purification in industrial processes. Among other positive outcomes, the company has succeeded in recovering valuable metals such as palladium, platinum and zinc from waste water. MAGICS Instruments from Geel designs semiconductor chips and intelligent sensors that can withstand extreme conditions such as nuclear environments, space travel and offshore locations.

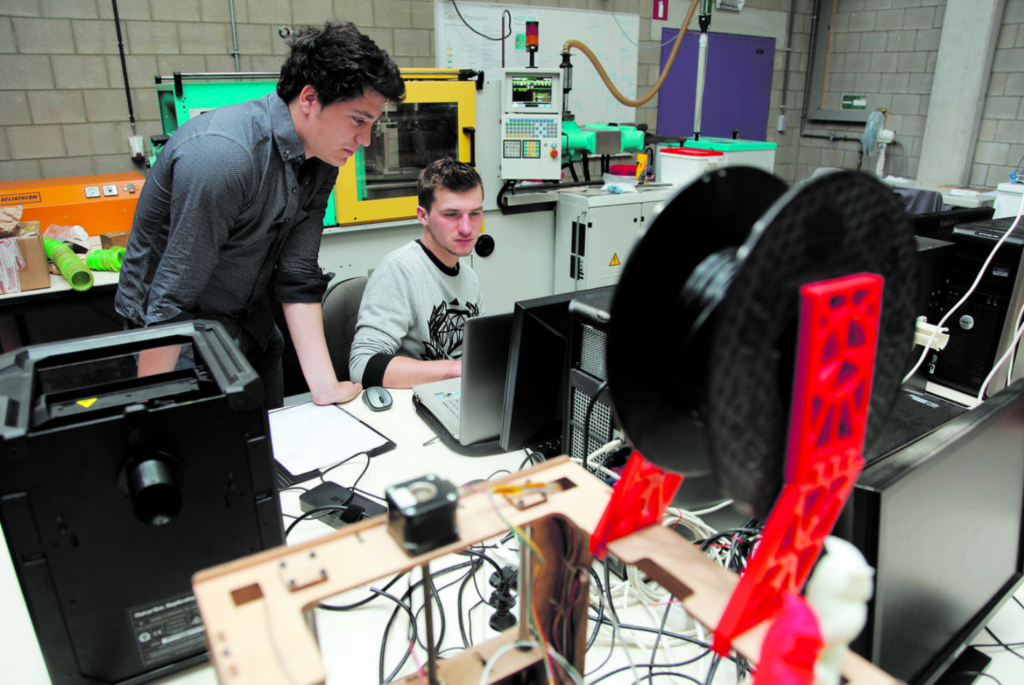

Innovative project engineers

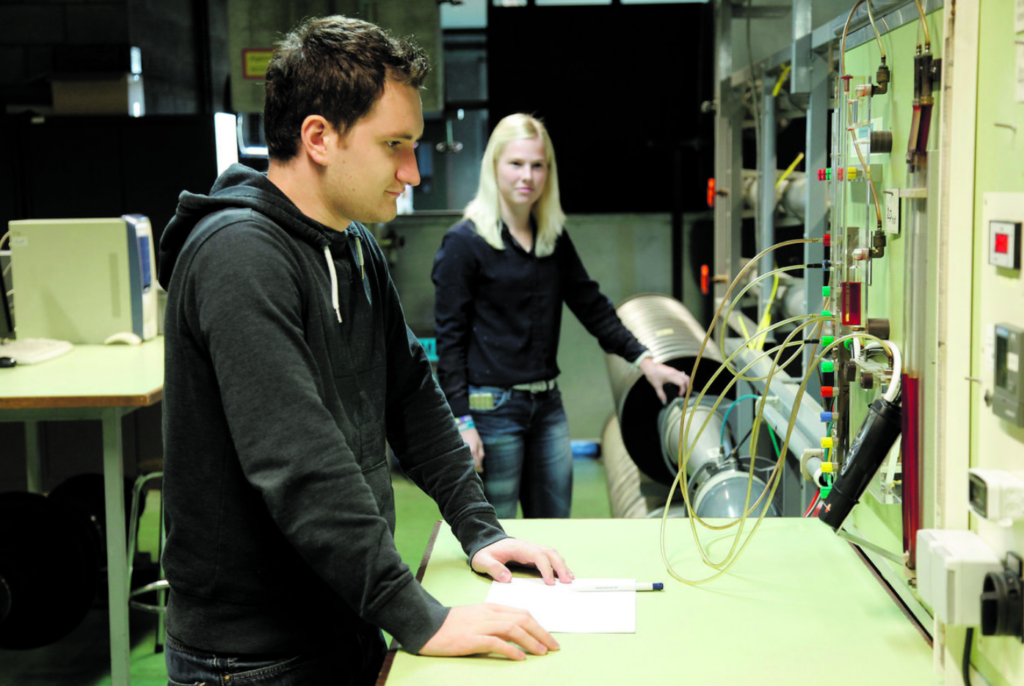

For our campuses, collaboration with companies, local and regional government and other educational and research institutions such as VITO is essential. Whether it concerns initiating an innovative project or developing a new product, KU Leuven researchers, teachers and students work together to find solutions. Project engineers are responsible for an important part of this work. In fact, most of them are following a doctoral programme at our institution. This is both unique and important, as their academic trajectory allows them to develop both research competencies and innovation skills such as: dealing with complexity, uncertainty and change, developing business cases, project management, taking responsibility in multidisciplinary teams, entrepreneurship and more.

Range of technological topics

KU Leuven campuses in the MechelenKempen region cover a wide range of technological topics. Research and education yield concrete applications that benefit our society.

Research in the life sciences, which is specific to the Geel campus, examines the entire chain from soil, plant and animal production to food processing. For example, there is a great deal of attention for biotic and abiotic threats to food production in both plants and animals, including insects. Whether insects will ever become a daily food staple in our regions is an open question, but in Geel we have already developed insect mincemeat; consumer panels are now being organised to voice their views on this topic. But that’s not all we do, of course. Other researchers are active in the field of precision livestock farming, and we also monitor nitrogen concentrations in agricultural areas.

In the field of civil engineering, we research how to optimise materials and the use of materials. We focus on the design and analysis of concrete, metal and hybrid components and structures. We make use of numerical modelling and extensive experimental (real-scale) campaigns in our own laboratory or in situ. We use these insights to develop new theoretical models and innovative construction techniques that we translate into practical guidelines and tools tailored to the construction sector.

In the broad field of electromechanics we focus on a multitude of applications in the Kempen-Mechelen region, such as the design and automation of machines, devices and systems and the development and optimisation of energy systems and production techniques (manufacturing). For the latter, its expertise in modern welding techniques gives Campus De Nayer a unique advantage. We also develop production processes for lightweight carbon composites, which leads to a wide range of applications from hydrogen storage tanks to unbreakable bicycle frames.

Research in chemistry focuses on techniques needed for a circular economy. We are, for instance, working on advanced purification techniques that remove toxic products from water, recover raw materials from residual flows and keep nitrate concentrations in agriculture and horticulture within acceptable limits.

Linking computer vision to artificial intelligence is the core business of the electronics and ICT group at the De Nayer Campus. Researchers have worked with an outside company to successfully develop a handy reading app for the visually impaired that has already been downloaded more than 100,000 times! Another application can be found in orchid nurseries, where smart cameras monitor the quality of these fragile flowers. Researchers at the Geel Campus design, model and test hyper-robust microchips that can withstand the most challenging conditions imaginable, such as ionizing radiation and extremely cold temperatures. In doing so, they provide highly reliable electronic systems for space travel, particle physics, and for all kinds of nuclear and medical applications.

Joining forces

The message is clear: companies and organisations that get stuck on a technological issue, that want to develop a prototype, or that want to optimise their production process find what they need at the Geel and De Nayer campuses. We are also actively cooperating with our partner Thomas More University of Applied Sciences at these locations. We share sites and expertise. Among our other partners, you’ll find the Open Manufacturing Campus (OMC), Campus Campina, Kempenpact2030, Blenders, IOK and VOKA Mechelen-Kempen,…

Wide range of lifelong learning

In the current environment, lifelong learning is an absolute must. That’s why KU Leuven offers an extensive range of continual training programmes, also for experienced engineers. Companies in the region that want to train their employees can contact KU Leuven. Advanced Master programmes, postgraduates or shorter certificate modules are also part of what’s on offer,

Whatever shape it takes, every collaboration between KU Leuven and the business community in the region bears fruit. To start, companies are given an insight into developments and research within the university. Additionally, they are at the head of the queue when it comes to recruiting new employees, an attractive asset now that the shortage in the labour market is becoming increasingly apparent. The annual Technology, ICT, Engineering and Management job fair, a joint initiative of KU Leuven and Thomas More, brings no fewer than 1,000 students into contact with 300 companies.

DE NAYER, SINT-KATELIJNE-WAVER CAMPUS

• Technologies for a circular economy

• 12,000m2 advanced lab space

• Annual job fair with more than 1,000 students and 300 companies

• Entrepreneurship hub Het Eiland

• Unique expertise in modern welding techniques

Use our QR code to find campus study programmes via the KU Leuven website.

GEEL CAMPUS

• Pioneers in agriculture and horticulture and in the world of food production and processing.

• Life sciences programme unique within KU Leuven

• SymBIOnt building with Insect Pilot Plant (additional test greenhouses are planned)

• Innovation Park next to campus

• Provincial Test Centres

• Entrepreneurship hub cocoon2440

Use our QR code to find campus study programmes via the KU Leuven website.

SymBIOnt: pilot plant investigates the sustainable potential of insects

Are insects the new game-changer in a sustainable food chain? A pilot plant from KU Leuven, Thomas More and VITO is already looking at how we can grow, harvest and process them more efficiently.

Insects have many advantages. Not only are they a potential food source for humans and animals, they can also process waste and be converted into biochemicals. KU Leuven’s Geel Campus has been a pioneer in research into the use of insects.

In the SymBIOnt building, the breeding of various insect species such as mealworms, fly larvae, crickets and grasshoppers, is being researched and optimised. These insects can feed on the residual flows of food processing companies and therefore form the missing link in a sustainable circular economy’s food system.

In Geel, research is also being conducted into the processing of insects. Using innovative techniques, they can be dried and processed into powders and pastes. This way they can be used in new foodstuffs and animal feeds, but also in chemical and pharmaceutical applications as so-called biochemicals.

Here, our researchers also study the interaction of insects with bacteria, fungi and plants. There’s also a link to plant research, another spearhead at the KU Leuven Geel Campus.

Plant research mainly focuses on the optimisation of cultivation methods and climate control. An emphasis is placed on the cultivation of plants with an increased resilience, the reduction of chemical crop protection and the reduction of the use of water and fertilizers.

SymBIOnt is a textbook example of collaboration. Various research groups conduct multidisciplinary research in the fields of soil, plants, micro-organisms and insects. Thomas More’s colleagues at Geel Campus and VITO are also involved. In addition to an area of 800m² for insect research, the building also contains four greenhouses and three 450m² air-conditioned growth rooms for plant research. KU Leuven has invested 3.4 million euros in the project.

KU Leuven was founded in 1425 and is not only one of the oldest but also the most innovative university in Europe (Reuters). With almost 60,000 students and more than 20,000 employees, it is also the largest university in Belgium. 15 faculties offer bachelor’s, master’s, doctoral and additional academic programmes at 10 locations in Flanders. The courses are based on the work of more than 7,000 researchers.