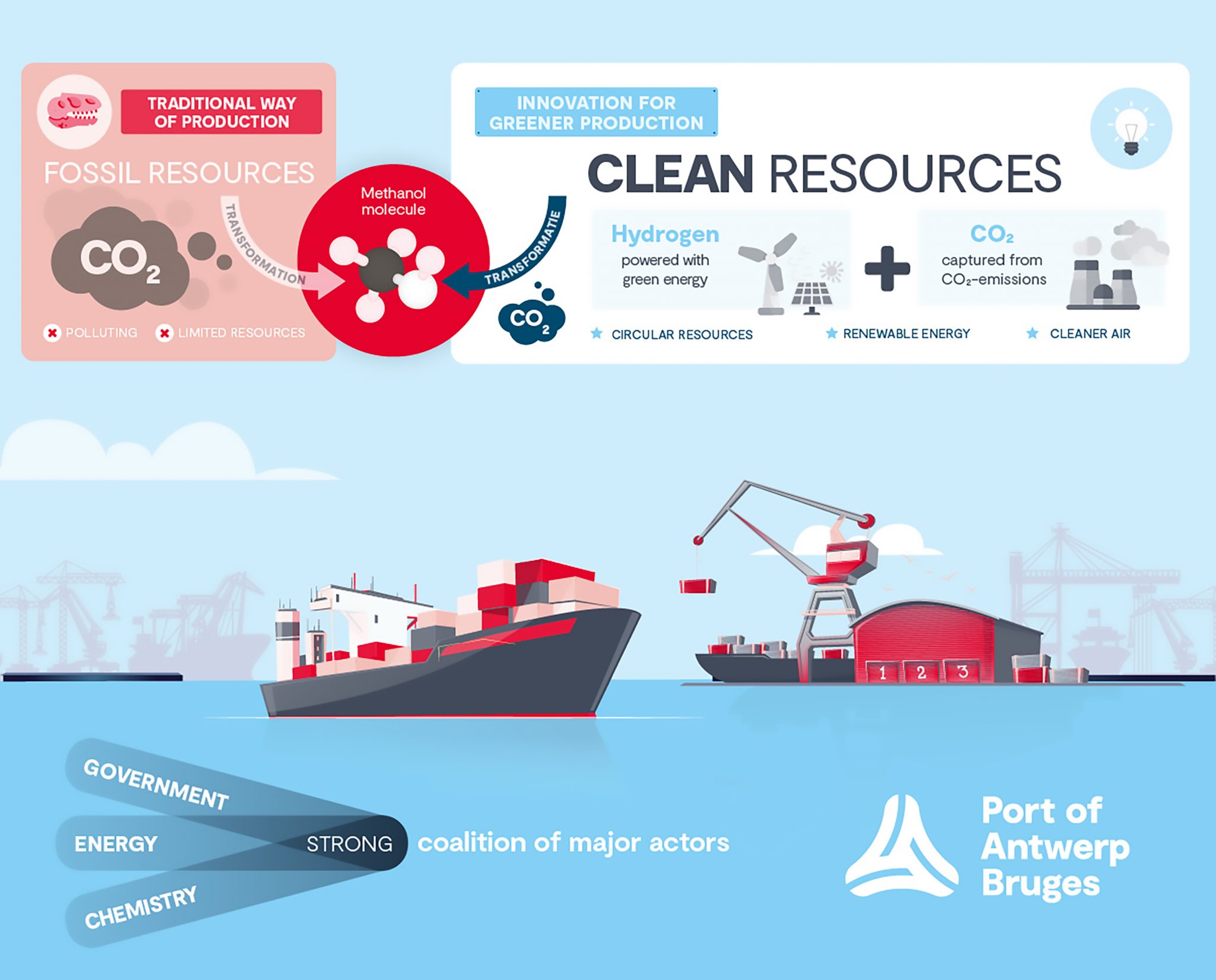

In 2022 the construction of the Power to Methanol Antwerp plant starts in the Port of Antwerp. The plant has a production capacity of 8,000 tonnes of sustainable methanol, produced from hydrogen generated from renewable energy and captured CO2. A consortium of seven companies is setting up the pilot plant on the INOVYN site, INEOS’ production plant at the port of Antwerp, home to the largest chemical cluster in Europe.

Methanol is an essential raw material that is used by industry in the port and can also be used in transport applications for fuels. Currently, methanol is largely produced using fossil-based raw materials, which emits carbon dioxide from the process.

Saving 10,000 tonnes of CO2 emissions per year

Just a Quick Note:

InnovationsOfTheWorld.com has partnered with Trade License Zone (TLZ) to support global innovators looking to expand internationally. Take advantage of the UAE’s Free Zones—enjoy streamlined setup, low corporate taxes, and a strategic gateway to the Middle East and beyond.

Get Your UAE Free Zone License Fast & Easy!With the innovative project of Power to Methanol, for each tonne of methanol produced at least one tonne of CO2 emissions will be avoided. A capacity of 8,000 tonnes of sustainable methanol per year, means a CO2 saving potential equivalent to 10,000 flights from Paris to New York and back, or the average annual emissions of 1,250 Belgians.

First for Belgium

Power to Methanol is developing an innovative technique to capture and reuse CO2. The Power to Methanol project will produce e-methanol by reusing captured CO2 in combination with hydrogen. This puts the production of e-methanol on a new track and is thus a first for Belgium. The plant will start operations by the end of 2023 or the beginning of 2024.

Plug & play

The plant will be built in the former fuel cell demo area on the INOVYN site in Lillo, providing an ideal plug & play site for the innovative project. The INEOS-company is an expert in the field of electrolysis and operation of chemical plants. Combined with the expertise of the other consortium partners from various sectors, all the knowledge and experience are available to make this project a success. The location also provides a high level of flexibility both on feedstock input, process capability, output and applications – key factors for the challenging project.

Futureproof product

Methanol or CH3 OH is the simplest alcohol chemical. It is formed of hydrogen, oxygen and a single carbon atom and is therefore a sustainable petrochemical feedstock and fuel. When made from renewable feedstocks as Power to Methanol is doing, methanol becomes a net carbon-neutral product.

Methanol is being employed around the globe in many innovative applications. e-methanol can be used to fuel ships, trucks or cars in an environmentally friendly way with its clean-burning properties and

lower emissions. In the chemical industry methanol serves as a basic product for a wide range of end products such as building materials, lightweight parts for cars or medical equipment.

Support by Flemish Government

The Flemish Government supports the innovative project by providing funding of €1 million and the project is also one of the Important Projects of Common European Interest that received co-financing. The Power to Methanol plant is an important link in the transition to CO2 storage and reuse and on the road to climate neutrality. The project shows in a very practical and innovative way the importance of industrial symbiosis as part of the energy transition. Power to Methanol is an initiative of ENGIE, Fluxys, Indaver, INOVYN-INEOS, Oiltanking, Port of Antwerp-Bruges and Participatie Maatschappij Vlaanderen. Combining know-how and best practices from all these sectors ensures a successful outcome for the exciting project.

Power to Methanol Antwerp partners:

- ENGIE’s purpose is to act to accelerate the transition towards a carbon neutral economy, by offering innovative solutions to its residential, professional and industrial customers, for a more economical and rational use of energy and greater comfort. As the country’s leading producer of renewable energy, ENGIE generates electricity close to its customers, thanks to a diversified, low-carbon generating fleet.

- Indaver operates specialist facilities and smart systems for waste management, processing around 5 million tonnes of waste annually for industry, government departments and households. Indaver

creates value from this waste by recovering materials and energy, thus playing an essential role in the circular economy. - INOVYN is a vinyl’s producer that ranks among the top three worldwide. Our portfolio consists of an extensive range of class leading products arranged across General Purpose Vinyl’s, Specialty Vinyl’s, Organic Chlorine Derivatives, Chlor Alkali and Electrochemical & Vinyl’s Technologies. INOVYN is part of INEOS.

- Fluxys is a fully independent gas infrastructure group active across Europe in gas transmission & storage and liquefied natural gas terminalling. Fluxys is committed to accommodate hydrogen, biomethane or any other carbon-neutral energy carrier of the future and to help developing Carbon Capture and Storage/Utilisation chains

- Oiltanking is one of the largest independent operators of tank terminals for oils, gases and chemicals worldwide. As Oiltanking we want to ensure “peace of mind in liquid storage logistics” going forward. This peace of mind should extend to all stakeholders. As a quality service provider, we focus on our customers’ needs by providing innovative solutions, responsibly and safely.

- Participatie Maatschappij Vlaanderen is a government-owned investment company that acquires stakes in the companies considered strategic by the Flemish government. It provides risk capital for companies at an early stage of development that speed up the transition to the circular economy.

- Port of Antwerp-Bruges is a limited liability company of public law and above all an active landlord for the port area. Energy transition is in the heart of our mission. As a community builder and innovation partner, we commit to boosting transition. We are a home port vital for a sustainable future.