Whether it’s developing new products, reducing costs, or increasing accessibility, innovations in manufacturing can improve the lives of companies and consumers alike. The Georgia Tech Manufacturing Institute (GTMI) is leading that charge with a mission to cultivate, scale, and integrate those innovations into the market — and develop the workforce needed to maintain them.

With increasing investments in revitalizing America’s manufacturing infrastructure, the U.S. is experiencing a manufacturing renaissance. GTMI convenes industry leaders, government partners, and top researchers to collaborate on the grand challenges facing manufacturing today: accelerating technology development and deployment; creating, maintaining, and filling quality jobs; ensuring global competitiveness; and advancing economic and environmental stability.

As one of Georgia Tech’s Interdisciplinary Research Institutes, GTMI has been a national leader in advanced manufacturing technology for decades. Through the design and development of artificial intelligence systems, secure digital manufacturing, additive and subtractive processes, and large-scale production enterprises, GTMI stands at the forefront of manufacturing innovation — and leverages state-of-the-art facilities to turn research breakthroughs into market-ready solutions.

“It’s not enough to have a good idea for a product or process. You need a business plan and a way to scale it up,” says Thomas Kurfess, GTMI executive director and Regents’ Professor in the George W. Woodruff School of Mechanical Engineering at Georgia Tech. “At GTMI, we are innovating at the speed of thought — leveraging our intellectual horsepower, world-class facilities, and industry partnerships to bring manufacturing innovations to market at scale as fast as we can think of them.”

From Lab to Market: Overcoming the “Valley of Death”

When it comes to manufacturing innovation, the “valley of death” — the gap between the lab and the industry floor where even the best discoveries often get lost — looms large.

“An individual researcher’s lab focuses on showing the innovation or the new science that they discovered,” says GTMI’s Aaron Stebner, professor and Eugene C. Gwaltney Jr. Chair in Manufacturing in mechanical engineering at Georgia Tech. “At that point, the business case hasn’t been made for the technology yet — there’s no testing on an industrial system to know if it breaks or if it scales up. A lot of innovation and scientific discovery dies there.”

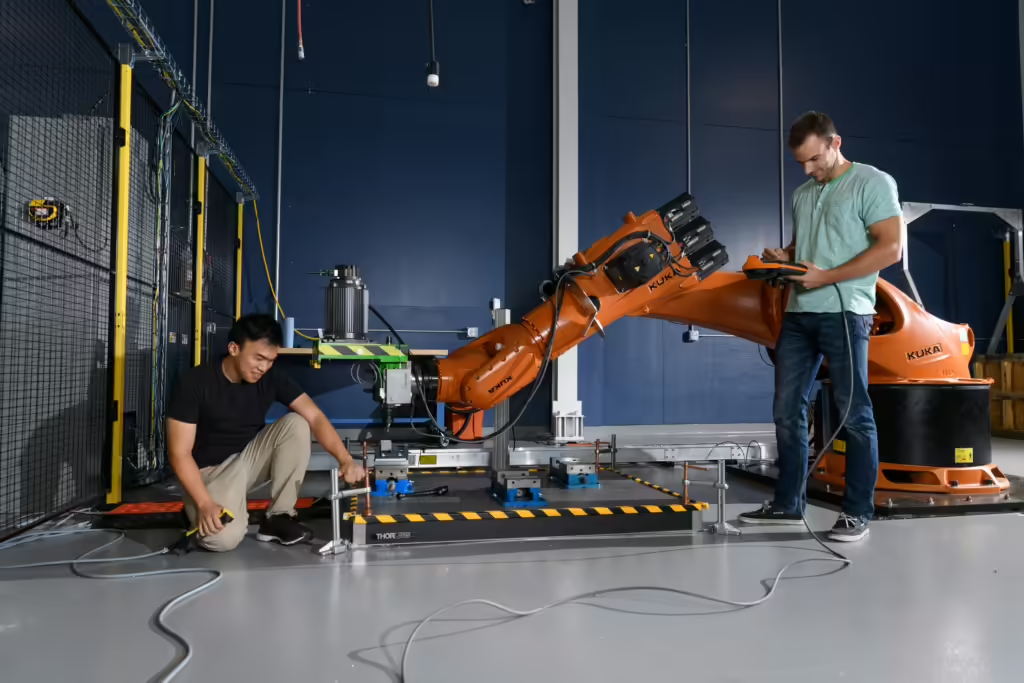

GTMI launched the Advanced Manufacturing Pilot Facility (AMPF) in 2017 to help bridge that gap. Located just north of Georgia Tech’s main campus, APMF is a 20,000-square-foot facility serving as a teaching laboratory, technology test bed, and workforce development space for manufacturing innovations. In addition to serving as the flagship facility for GTMI research, the AMPF is a user facility accessible to Georgia Tech’s industry partners as well as the Institute’s faculty, staff, and students.

“The pilot facility,” says Stebner, “is meant to be a place where stakeholders in academic research, government, industry, and workforce development can come together and develop the workforce that is needed for future technologies, as well as mature, de-risk, and develop business cases for new technologies — proving them out to the point where it makes sense for industry to pick them up.”

Bringing Manufacturing Into the 21st Century

Combined with industry-focused member groups like GTMI’s Manufacturing 4.0 Consortium, GTMI continues to work toward digitally advanced manufacturing through research in cybersecurity, data management, and data integration systems.

“So much of the manufacturing equipment used today has the advanced capabilities of a smartphone, but is being used like a flip phone,” says Kurfess. “We’re connecting Georgia manufacturers with companies like Microsoft and Intel to bring them into the 21st century.”

With a $60 million expansion to AMPF slated to triple the size of the facility and increase robotic automation and digital manufacturing capabilities, GTMI is also working to advance market adoption of artificial intelligence in manufacturing.

“This will be the first facility of this size that’s being intentionally designed to enable AI to perform research and development in materials and manufacturing at the same time,” said Stebner, “setting up GTMI as not just a leader in Georgia, but a leader in automation and AI in manufacturing across the country.”