South Australian-owned FCT is a global engineering group with three specialist divisions: Combustion, Flames, and ACTech. Incorporated in 1984, the Group’s Head Office is based in Thebarton, while additional key offices are located in Austria, Brazil, China, and the USA.

While FCT Flames has in the past enjoyed prominent publicity with their high-profile entertainment flame effects seen at events such as the Olympic Games, it is actually the Group’s industrial combustion business that generates the most revenue, with FCT Combustion having become the world’s leading supplier of burner systems to the lucrative iron ore pelletizing market over the past 5 years.

The third division within the Group is FCT ACTech. The company delivers complete, end-to-end analytical solutions for the cement, mining, and mineral processing industries. Their innovative instruments for process control allow customers to improve their profitability and reduce their carbon footprint.

So, how did the South Australian owned FCT Group grow to dominate global markets? The answer lies in their commitment to innovation, a strong belief in their products, tenacity, strategic planning, and having a very good team of committed experts to ensure FCT can carry out the engineering excellence that it promises.

FCT was originally founded in England in 1984, however the current ownership took over the company in 1999 and moved it to their hometown of Adelaide. At the time of the take-over, FCT had a just small customer base in the cement industry to whom they supplied one specific type of burner.

FCT had a reputation for excellence in the niche market they served, but they were small fish in a big pond. Then, two things happened.

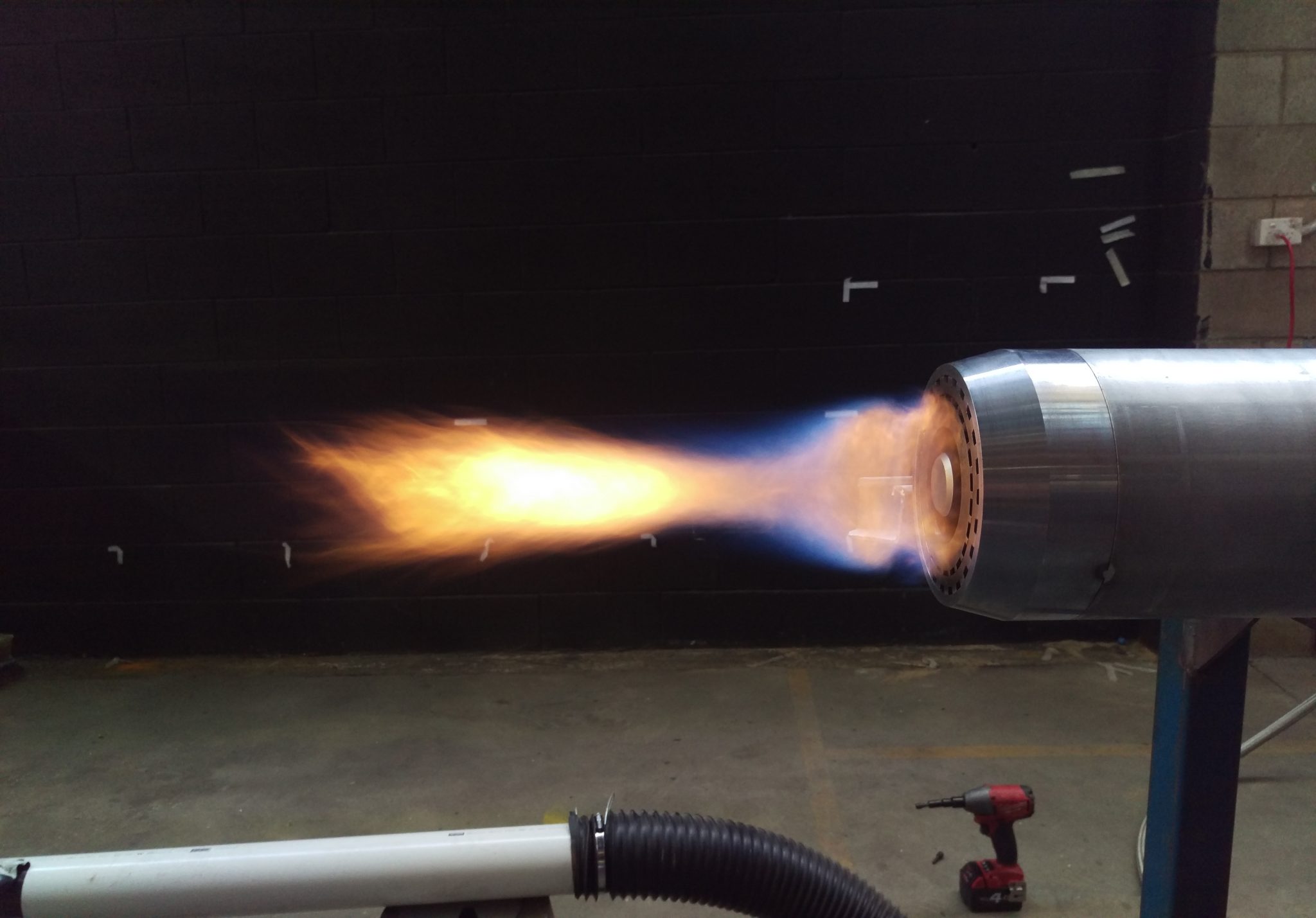

The first was the development of a unique, low NOx burner system for natural gas, called Gyro-Therm™, in partnership with the University of Adelaide. The patented Gyro-Therm™ design is still unlike any other competitor offering on the market and remains one of the company’s best-selling products.

This development saw FCT break into the broader North American lime and cement markets, where natural gas usage is prominent. Innovative development of its solid fuel burners including the ability to burn large amounts of renewable fuels has since enabled FCT to deliver proven burner technology to all corners of the globe , including Europe, the Middle East, South America, and Asia.

This international success led to the second key event; it gave FCT the confidence to apply their expertise in new ways. Applying their combustion skillset to engineering ornamental flames rather than just industrial, FCT won the right to design the burner system for the Olympic torches and the opening ceremony cauldron at the 2000 Sydney Olympic Games.

FCT quickly became the global market leader in ornamental flames, supplying an array of major sporting events. But, despite this achievement, the leadership team realised that the sporting events industry is only so big, and a new strategy was required to secure the continued growth of FCT Group.

Increasing the presence of the industrial combustion side of the business became a priority and FCT decided to bring the company closer to potential markets. Over the course of the past decade, FCT has set up operational hubs across the Americas, Europe, and Asia to offer local sales, support, and engineering to customers.

This bold move has led to exponential growth and FCT Combustion is now a leading burner supplier not just to the cement and lime industries, but also to pulp and paper, alumina, nickel, minerals including spodumene, and most significantly, iron ore pelletising.

Heavy investments in R&D have also expanded FCT’s product range.

The company offers a variety of state-of-the-art burners and hot gas generators to suit alternative and emerging fuel sources, which can be applied to many high temperature processing industries to assist plants on their journey to decarbonisation.

Notably, FCT’s I-Jet burner technology for the iron ore pelletizing industry has driven dramatic growth, and the company has fitted out more than a dozen plants with burner equipment in countries such as Sweden, Algeria, China, Brazil, and the United States. A new, low NOx hydrogen version of the I-Jet is under development, with testing to take place in Sweden in 2023.

“Innovation is at the heart of what we do. We always want to ensure we can offer our partners the best available technologies to meet their goals. This is why we continue to invest in R&D,” said FCT Group CEO Adriano Greco.

“Hydrogen and alternative fuel usage is an important factor in decarbonisation, and FCT is proud to help our clients worldwide in

achieving that goal.”

The R&D investment has also seen the addition of two innovative clay calcining technologies, FlashCalx™ and RotaCalx™. With the cement industry accounting for approximately 8% of man-made CO2 emissions, the products enable manufacturers to adopt a new ingredient mix to produce ‘green cement’, using clay as a partial substitute and decreasing the limestone content. The switch to green cement processing can reduce emissions by up to 40%.

“Heavy industries across the world are focused on reducing their carbon footprint, and moving forward, FCT will continue to meet their needs with an evolving range of products designed and delivered by our experienced team,” said Greco.

Despite its international success, FCT maintains its Head Office in Adelaide and has won two major export awards in Australia due to its sound business strategy, successful growth, and commitment to innovation.