Headquartered in Warren, NJ, Chromis Technologies is one of only a few companies in the world capable of making amorphous fluoropolymers – advanced materials with very unique properties – used in myriad industrial applications, including clean energy production, biomedical and chemical sensors, optical fiber, 3D printing, semiconductor manufacturing, anti-reflective coatings, and many others.

Reducing Greenhouse Gas Emissions

Natural gas is considered the most environmentally-friendly carbon-based fuel. Its global production has been steadily increasing, due in large part to the fracking revolution. Natural gas as produced at the wellhead, however, typically contains a mix of components besides methane, including heavier hydrocarbons (e.g., ethane, propane, butane), as well as impurities such as carbon dioxide. The latter is a well-known greenhouse gas.

Chromis makes amorphous fluoropolymers optimized for membranes that can separate carbon dioxide from methane in natural gas production. A membrane is basically a barrier that allows certain gases to pass through it, while blocking others. Once separated from methane, the carbon dioxide can be “captured” by pumping it back into the ground to enhance production of the well, or catalyzed and transformed into renewable feedstocks (e.g., ethylene, propylene) for the chemical and plastics industries, instead of being released into the atmosphere where it would contribute to global warming.

Enabling the “Hydrogen Economy”

Fuel cells generate electricity and heat using an electrochemical reaction, not combustion, emitting only water if hydrogen is used as the fuel source. They are a critical component of the “hydrogen economy”, a term which refers to the vision of hydrogen as a low-carbon energy source for distributed power generation and intermittent-source (e.g., solar, wind) energy storage, and to replace natural gas for heating and gasoline for vehicle transportation. Today fuel cells are contributing to environmental stewardship and helping corporations achieve strategic emissions reduction goals and commitments.

Just a Quick Note:

InnovationsOfTheWorld.com has partnered with Trade License Zone (TLZ) to support global innovators looking to expand internationally. Take advantage of the UAE’s Free Zones—enjoy streamlined setup, low corporate taxes, and a strategic gateway to the Middle East and beyond.

Get Your UAE Free Zone License Fast & Easy!Membrane Electrode Assemblies (“MEAs”) are the heart of fuel cells, comprising a membrane, catalyst layers (anode and cathode), and diffusion media. The membrane component of a MEA can let protons pass through from anode to cathode, but not electrons (a “Proton Exchange Membrane”) or vice-versa (an “Anion Exchange Membrane”). Chromis makes amorphous fluoropolymers which improve the performance and reduce the cost of both types of membranes, making fuel cells an increasingly viable alternative to other forms of clean energy.

Transmitting Data at the Speed of Light

Higher data rates are driving the displacement of copper wire cables by optical fiber links in data center and consumer electronics applications over increasingly shorter distances. The advent of active optical cables (“AOCs”) has made this transition very convenient. An AOC has the same standard electrical inputs (e.g., HDMI) as a traditional copper-wire cable, but uses optical fiber for high-speed data transmission “between the connectors”. Sophisticated technology in the connectors performs electrical-to-optical conversion at the source and then reverses it at the destination.

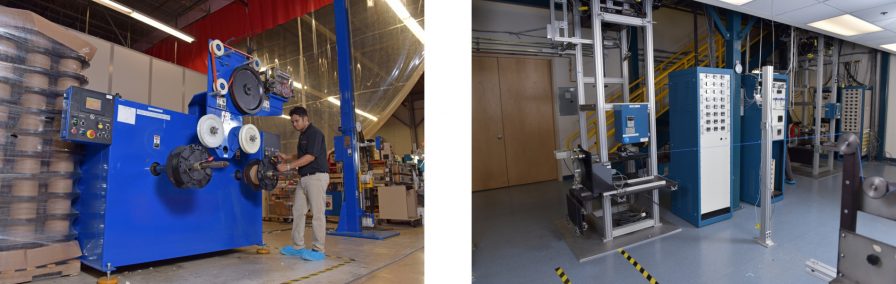

Using our optical-grade amorphous fluoropolymers, high-bandwidth, low-attenuation optical fiber under our GigaPOF® brand at our Warren, NJ extrusion facility. You can find Chromis GigaPOF® polymer optical fibers in AOCs and other high-speed cables wherever greater durability and resistance to breakage from tight bends and kinks compared to glass optical fibers are required.

Innovation via “Rational Design”

We work with our industry partners to discover unmet needs and unique problems that can be solved by our custom synthesis technology platform. These market-driven insights, and our deep knowledge of specialized fluorochemistry techniques, inform the formulation of new materials whose properties and performance are optimized for the specific application. This “rational design” approach to innovation reflects our commitment to using our capabilities to make advanced materials for a better world.