B4Plastics is a Belgian Biopolymer Tech Company specialised in: Creating (R&D), Producing (up to kton), Selling and Licensing novel biomaterials, based on a unique range of Bio Based Building Blocks (hence the B4), tailored to an extended variety of applications.

This Belgian-based company, located in Limburg, is a pioneer in bioplastics production. With its “Bio-Based Building Blocks”, B4Plastics is recognized as a global leader within the emerging bioeconomy. The company’s team of 27 colleagues, consistently pushes forward in developing biopolymer products derived from renewable resources, including sugar beet waste, wood by-products, and vegetable oils.

These materials help reduce or eliminate dependency on non-renewable fossil-based resources, while also significantly decreasing greenhouse gas emissions — a proactive step in combating climate change. Through this leading-edge approach, B4Plastics advances the development of a sustainable future.

Some of the company’s innovative bioplastics are designed to degrade naturally in the environment, leaving no harmful residues or microplastics behind. This eco-conscious solution is particularly critical given the increasing concerns around global plastic pollution, especially from high-wear products such as footwear and trimming lines.

Just a Quick Note:

InnovationsOfTheWorld.com has partnered with Trade License Zone (TLZ) to support global innovators looking to expand internationally. Take advantage of the UAE’s Free Zones—enjoy streamlined setup, low corporate taxes, and a strategic gateway to the Middle East and beyond.

Get Your UAE Free Zone License Fast & Easy!B4Plastics’ commitment to reducing plastic waste and safeguarding ecosystems strengthens its role as an influential player in the green transition.

The company has an R&D Centre for the screening and scaling of new Biomaterials from gram to ton scale. Beyond that, their Production Centre supplies ready-made Biomaterials up to 1 Kton. Furthermore, their Tech Platforms are organised in a Licensing House for Tech Transfers to a companies own equipment and last but not least, they transform their technologies into prototyped bio-end-products that one can use and experience in their daily life – eg.: Tie wraps, brushes, drinking straws, 3D Filament, cutting boards, bioclips for plants and vegetables, plant pots,…

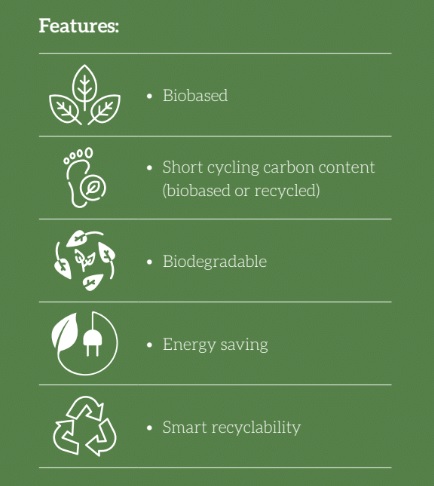

Their materials provide loads of new sustainability features*, not compromising on the performance of traditional fossil-based materials.