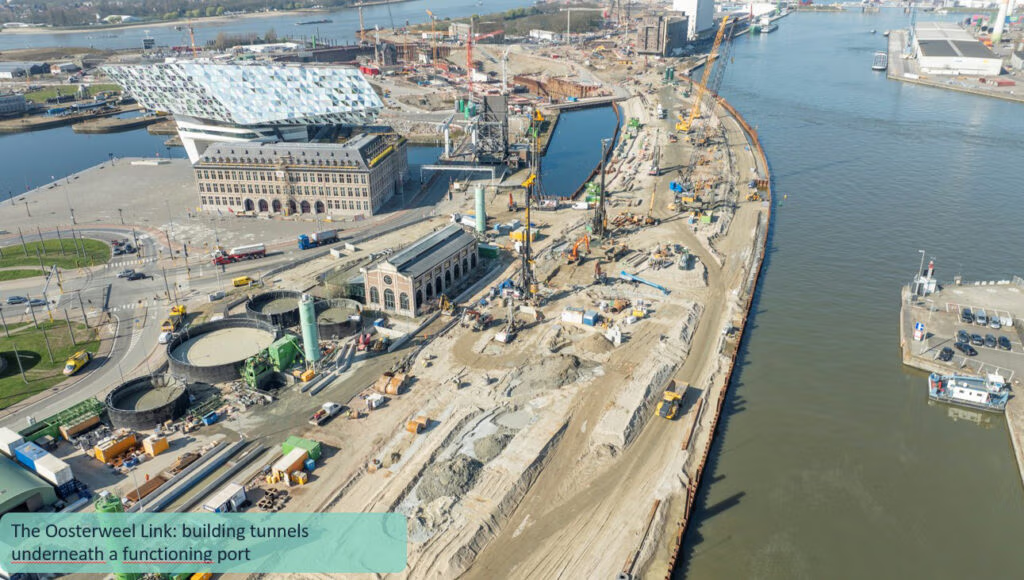

The Oosterweel Link is a monumental infrastructure project aimed at completing the ringway around Antwerp, Belgium. This project, coordinated by Lantis (www.lantis.be), is designed to alleviate traffic congestion and improve connectivity, integrating groundbreaking techniques and sustainable practices. The innovative approach of this megaproject sets a new standard in Belgium with a focus on maximizing societal added value. This pursuit started well before the design phase and construction start, involving intensive collaboration between governments, mobility partners, citizen groups, and experts. The scale, complexity, impact, and multigenerational nature of the project present an opportunity to inspire and transform the Belgian construction sector.

A virtual building site

One particularly innovative aspect of the Oosterweel Link constructionis the approach to digitalization. The project is first built entirely digitally before physical building begins, covering the entire life cycle from design to construction, maintenance, and operation. This reduces construction failure costs, typically 5 to 10% of the investment. In doing so, Lantis optimizes processes and fosters thinking in terms of a circular economy. This technology can also be applied to other construction or urban planning projects, offering lasting added value for the sector.

In 2024, Lantis, in close collaboration with contractors, defined overarching data and information standards for sustainable life cycle management. These were rolled out across various sub-projects and will be key to a sustainable and future-proof transfer from construction to operation, management, and maintenance.

Innovation in contracting

The innovative approach also extends to contracting. For two of the five Oosterweel building zones, NEC4 contracts were signed. NEC stands for New Engineering Contract, a model originating in the Anglo-Saxon world, now being used on the European mainland for the first time. This contract type is considered a game-changer in risk management because it settles on actual cost, prioritizing cost control, which is essential for a project of Oosterweel’s magnitude. With a traditional contract model and risk distribution, it likely would have been very difficult to find contractors willing to take on a project of this magnitude.

… and in execution

Another key innovation lies in the construction of tunnel segments using advanced prefabrication methods. These segments are assembled off-site, significantly reducing environmental disruption. By limiting on-site activities such as heavy machinery operation and excavation, this approach prevents damage to local ecosystems and minimizes noise and pollution that would otherwise affect nearby communities. Prefabrication also allows for a more controlled construction process, ensuring greater precision, quality, and cost control.

Innovate to improve

The project integrates cutting-edge noise barriers designed not only to reduce sound pollution but also to blend harmoniously with the surrounding environment. These barriers employ innovative materials and structural designs to absorb and deflect noise effectively, ensuring that residential areas and wildlife habitats remain unaffected by the bustling activity of the construction and future traffic. Some barriers are enhanced with vegetation, creating an aesthetic appeal while contributing to biodiversity preservation.

In prioritizing sustainability, the Oosterweel Link sites employ materials with a low carbon footprint. This involves using recycled and locally sourced materials to reduce transportation emissions and energy consumption. The project also experiments with advanced concrete mixes and other eco-friendly alternatives that offer durability while significantly lowering greenhouse gas emissions. These sustainable material choices underscore the commitment to eco-conscious construction.

Energy optimization during construction is another hallmark of the Oosterweel project. Innovative techniques such as energy-efficient machinery, renewable energy sources like solar panels, and smart construction logistics ensure that energy use is minimized without compromising the pace or quality of the work. This approach not only reduces operational costs but also aligns with global efforts to lower energy consumption and carbon emissions.

Improved safety through innovation

The safety approach on the Oosterweel construction sites has not gone unnoticed. The number of incidents on the building sites has been significantly lower than average in the construction sector. EU commissioner Roxana Minzatu emphasized this during a site visit in March 2025, noting Lantis’ commitment to fair and responsible business practices in the construction sector. In 2024, Prebes — the largest professional organization of prevention advisors in Belgium — visited Oosterweel with several of its members. That same year, Lantis also contributed to the publication of a document in the Netherlands on safety in tunnel construction. As part of the European Week for Safety and Health at Work, Lantis received an award for launching an innovative navigation simulator. This simulator provides training opportunities for maritime traffic that must pass through the construction zone during the works on the canal tunnels of the Oosterweel project.

Innovate thinking

Finally, the Oosterweel project reflects an adaptive approach to long-term urban planning. By incorporating flood-resilient designs, the Oosterweel Link prepares the region for potential climate challenges. Green zones and urban landscaping integrated into the infrastructure create versatile spaces that can serve ecological, recreational, and aesthetic purposes. This foresight demonstrates a balance between modern mobility needs and the sustainable evolution of urban spaces.

Through its blend of engineering ingenuity and environmental consciousness, this mega project not only addresses contemporary mobility needs but also aspires to set a benchmark for future infrastructure developments.