OUR GOAL

Our goal is helping companies to solve their mechanical challenges.

Our innovation culture, eye for detail and focus on quality is what attracts customers such as Total, CNH, DEME, ArcelorMittal or Pfizer. From the moment a customer submits a problem to us, he feels the eagerness of our designers to create a unique and innovative solution.

All our employees share the same passion for building things, this allows us to increase the volume and velocity of new initiatives and, obviously, grow our business.

OUR HISTORY

Patrick De Bie started some 20 years ago providing engineering and design solutions, in addition to his job as a heavy lifting engineer. In 2013 he decided to incorporate 3D Cadworks. Since then, the company evolved to a strong and versatile team of around 15 full-time engineers, product designers and technical draughtsmen and an extensive network of specialised freelancers, production companies and suppliers.

OUR FUTURE

Next to constant technical and mechanical innovation, 3D Cadworks is also a leader in internal diversification based on its experience. Indeed, the company has since divided itself into several companies, each dedicated to providing specific services to their customers.

In order to provide an even better service to our customers, 3DCadworks is evolving into a group of independent business units. Each business unit provides specific services and expertise.

ENGINEERING

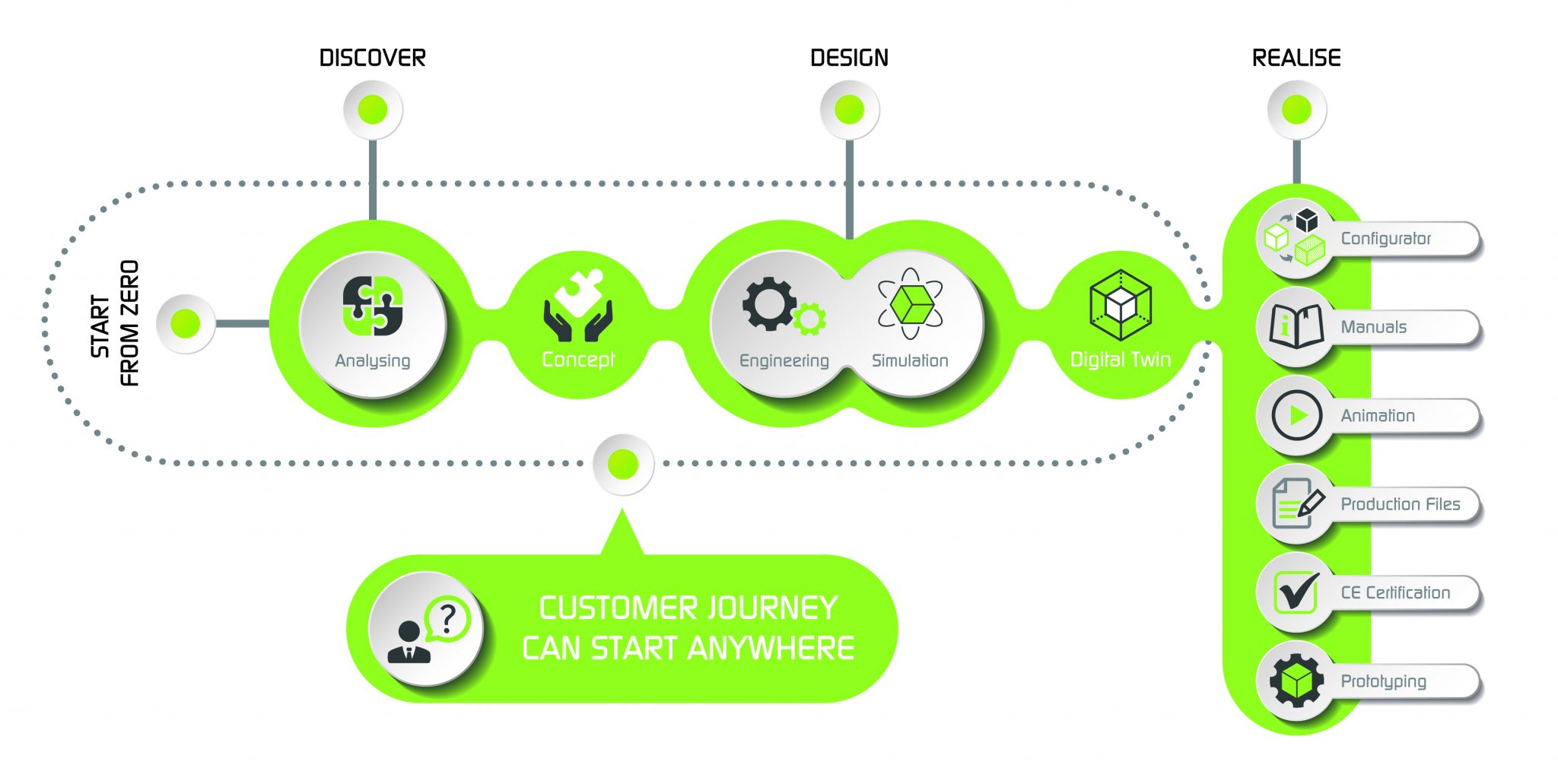

Caden develops innovative mechanical solutions to solve the problems encountered by its customers in a wide range of industries: from pharmaceuticals and chemicals to heavy lifting and traditional mechanical engineering.

Next to design, often involving products that do not fall within the scope of traditional engineering, careful attention is given to the aesthetic appearance, user interaction, ergonomics, sustainability and experience.

A crucial part of a digital design process is a fully virtual 3D model of a physical object. Thanks to a digital twin, in a short time a part can be simplified, the weight reduced or a smarter and cheaper production process established.

Very often this results in physically building a prototype or the number one of a series. Exceptionally small series can be produced as well.

Careful attention is given to the aesthetic appearance, user interaction, ergonomics, sustainability and user experience. We achieve this through a digital design process based on a fully virtual 3D model of a physical object. This digital twin allows for smooth design reviews in close interactions with the customer, leading to simplified parts, weight reduction, smarter or cheaper production or easier maintenance.

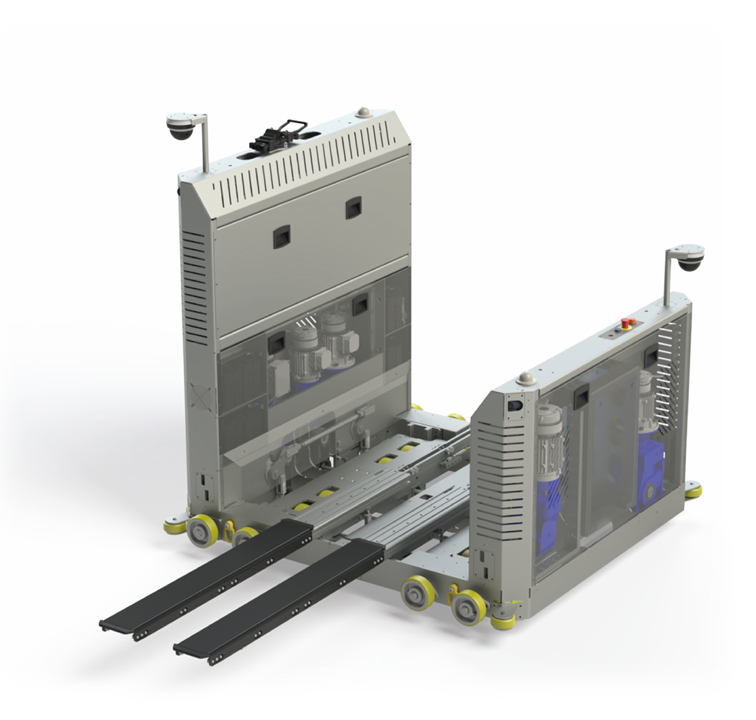

TECHNICAL PRODUCTION

Innovation is more than just theory. At Tepro, engineering becomes reality. The designs are being effectively produced and marketed. These state-of-the-art products can be one-offs for a specific customer or products that are offered to a wider public under the TEPRO brand. This allows us to share our innovations.

TECHNICAL DOCUMENTATION

Captis delivers a wide range of technical documentation, including CE directives, risk analysis, technical construction files, assembly instructions, etc.

We move from printed material to digital, incorporating augmented (AR) and virtual (VR) reality to create interactive 3D manuals and documentation that can be accessed on different devices. Through QR codes or AI based object recognition we provide live up-to-date data on parts, links to assembly instructions or ordering services.

CONFIGURATORS

Yucon is a configurator platform to automate repetitive tasks in a design process, providing automatic CTO (Configure to order) or CPQ (Configure price-quality). Through a simple interface, any employee can set a number of parameters of a product, leading to an automatically generated 3D model, workshop drawing, quotation, production file or other output.

ACADEMY

aCADemy offers specialised SolidWorks training sessions. These sessions are offered in several modules such as BASIC SolidWorks for less experienced users, or ADVANCED SolidWorks for CAD professionals seeking a higher level of expertise. We also offer customised training sessions or 1-on-1 training, based on specific customer requests.

All our training courses are practice oriented, the acquired skills are thus immediately applicable in the work environment.