UP Catalyst is a European deep tech company headquartered in Estonia that produces climate-neutral carbon materials—such as battery-grade graphite and carbon nanotubes—directly from industrial CO2 emissions. Founded in 2019 by Dr. Gary Urb, Dr. Sander Ratso, Dr. Kätlin Kaare and Dr. Ivar Kruusenberg, the company is on a mission to reinforce Europe’s critical raw material supply chains by offering locally produced, high-performance, and low-cost alternatives to fossil-based carbon materials. These advanced materials are essential across a wide range of industries, including electric vehicle batteries, defence, steel manufacturing, and polymers.

The problem UP Catalyst is solving is twofold: Europe’s heavy reliance on imported graphite—primarily from China—and the environmental and social impact of conventional graphite production. Currently, China controls over 80% of global graphite supply. Conventional graphite is typically produced through energy-intensive processes using coal tar pitch or petroleum coke, often powered by coal-based electricity. For every ton produced, up to 42 tones of CO2 are released into the atmosphere. Multiply that by the scale of global demand, and the result is millions of tonnes of greenhouse gases each year.

Beyond its environmental cost, this dependency carriers a deeper risk. Graphite is not just for batteries—it is built into the backbone of defence and is used in main battle tanks, fighter aircraft, submarines, ammunition, and many more. Each shipment arriving from overseas holds more than material—it holds the readiness of a nation’s defence.

“Europe urgently needs domestic solutions for graphite production. We cannot build a green energy transition on dirty, unsustainable raw materials—and we certainly can’t rely on building our battle tanks and submarines with critical materials we don’t produce ourselves and must import from a single third country,” says Teele Niidas, COO of UP Catalyst. “UP Catalyst is proud to offer a clean, cost-competitive alternative to fossil-derived graphite—and most importantly, one that’s made in Europe, from waste CO2 emissions that would otherwise be released into the atmosphere.”

To achieve this, UP Catalyst has developed a proprietary process using Molten Salt CO2 Capture and Electrochemical Conversion (MSCC-EC) technology. The roots of this technology trace back to NASA, where it was designed to produce oxygen on spacecraft. UP Catalyst turned its purpose around—they do not focus on oxygen, but on producing carbon.

The process requires only CO2 and green electricity for production, making it inherently sustainable. According to a Life Cycle Assessment conducted by the Research Institutes of Sweden (RISE) and verified by Bureau Veritas, the end product is climate-neutral.

Dr. Sebastian Pohlmann, CTO of UP Catalyst, explains how the technology works:

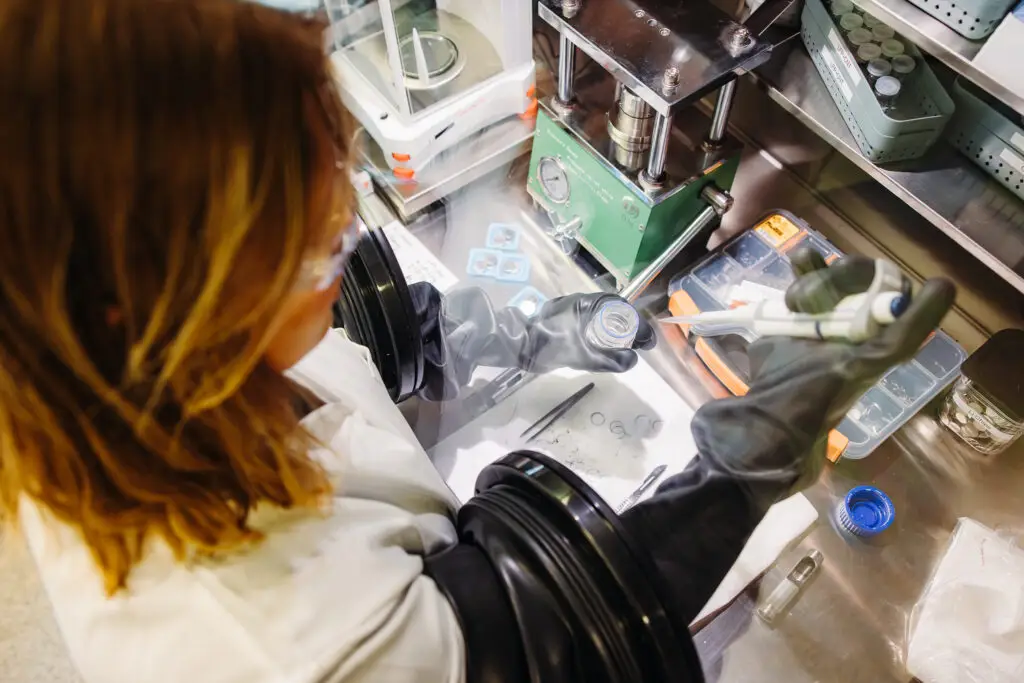

Concentrated CO2 from industrial emissions is introduced into our molten salt electrolysis reactor. At a temperature below 800°C, the gas is dissolved and electrochemically split into oxygen and carbon through electrolysis. As a result, oxygen is released into the atmosphere, while the carbon is collected and then purified. Depending on the electrolysis conditions, the carbon can be deposited as either graphite or carbon nanotubes.

The main difference from conventional production methods is that our process operates at 700°-750° C and completes in 8–10 hours, whereas conventional graphite production requires temperatures of up to 2800°C and can take up to four weeks.

UP Catalyst has successfully transitioned from lab-scale reactors to operating a pilot reactor that produces ton-scale quantities of high-quality carbon materials annually. To further support its growth, the company has set up its own battery testing lab. This lab helps speed up prototyping, test material performance, and work closely with clients and partners across the energy storage industry. It also allows UP Catalyst to customise its materials to meet specific customer needs and help get them into real-world use more quickly.

In 2025, the European Commission recognised UP Catalyst as a Strategic Project under the Critical Raw Materials Act (CRMA) for its contribution to European resilience in the battery supply chain. The company’s technology will help the EU meet its raw material processing targets without compromising sustainability goals.

UP Catalyst CFO, Rait Maasikas, commented on company future: “Looking ahead, our goal is to supply at least 30 000 tonnes of battery-grade graphite annually by 2030, fostering high-skill job creation, boosting the local economy, and strengthening the supply chain of critical raw materials in Europe. We are confident there is a huge and growing market for our product—especially because we don’t charge a green premium. Unlike many other carbon capture and utilisation or cleantech companies, our product just happens to be sustainable at no additional cost, making the choice not only environmentally responsible but also economically obvious”.