Fashion’s Pollution Problem

The $2.5 trillion fashion industry is one of the top-most polluting industries in the world, generating 10% of global greenhouse gas emissions. Specifically, the heavy reliance by the industry on synthetic, petroleum-derived, fabrics such as polyester, is projected to create over a quarter of the world’s carbon emissions by 2050, according to the Ellen MacArthur Foundation. Unlike its bio-based counterparts, such as cotton, wool or silk, polyester does not biodegrade, and its synthetic production is estimated to consume 70 million barrels of oil each year. With 1/3 of the industry committing to net-zero carbon impact by 2050 through the G7 Summit Fashion Pact, the $105 billion polyester sector is poised for radical disruption.

The Alternative: ALT TEX

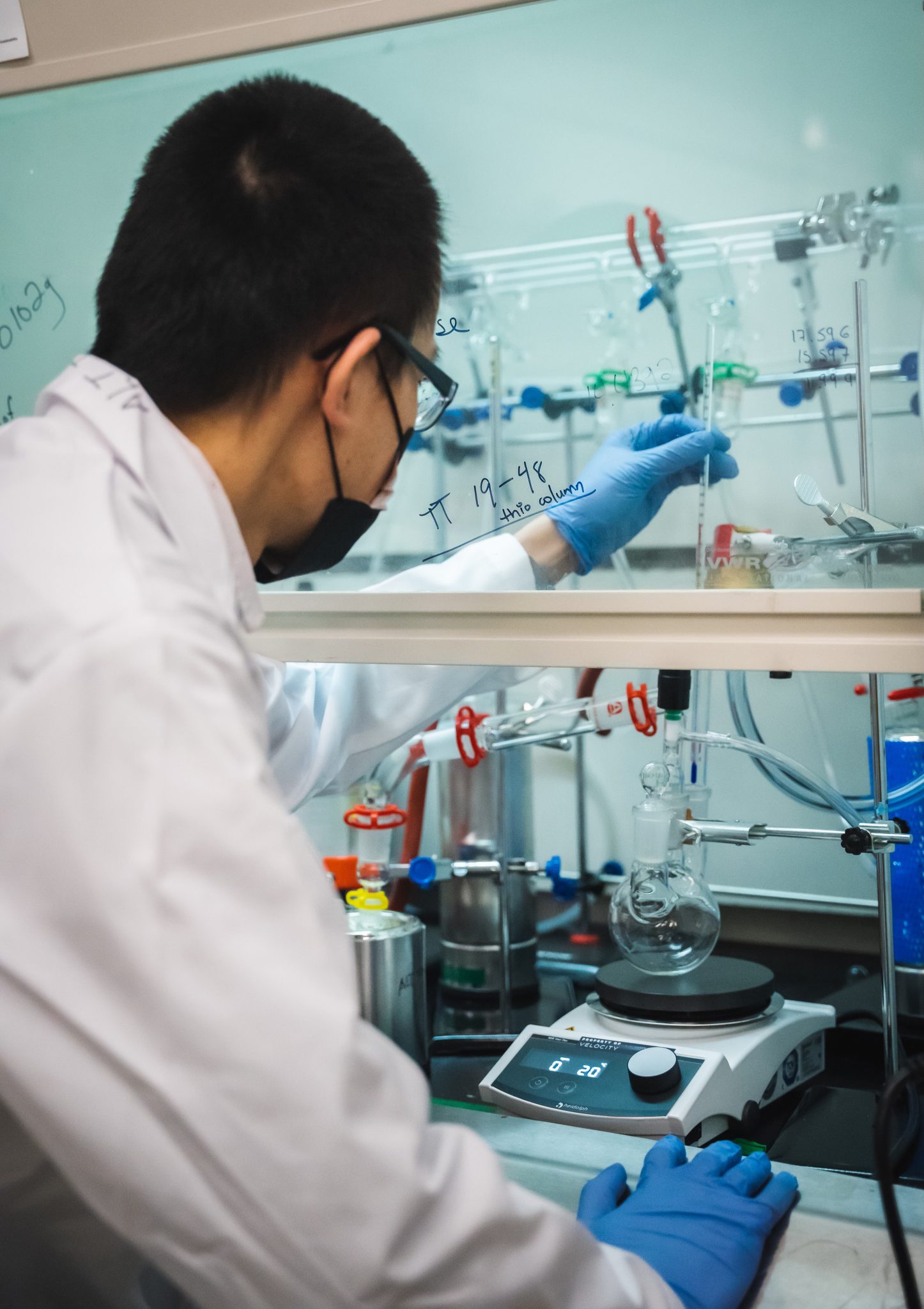

Short for “alternative textiles”, ALT TEX reduces the fashion industry’s dependence on fossil fuels through circular, biodegradable and carbon neutral textiles engineered from one of the world’s largest landfill contributors – food waste. The company’s patent-pending biomaterial technology re-engineers sugars found in landfill-destined food waste into high performance, polyester-like textiles. Using the existing textile manufacturing supply chain, the fibre is woven or knitted into fabrics, for sale to fashion brands. The closed-loop, waste-to-wardrobe material is aimed to replace polyester, which makes up over 60% of textile manufacturing.

ALT TEX has three key advantages:

1. Sustainability: one shirt produced with ALT TEX fabric can divert 1kg of food waste from landfills, up to 9kg of carbon emissions from the atmosphere and 4g of microplastics from polluting the ocean. The ALT TEX material is industrially biodegradable, enabling waste diversion of fabrics from landfill where current polyester counterparts take thousands of years to degrade.

2. Economics: The ALT TEX fabric is projected to be a fraction of the cost vs specialised sustainable alternatives as it fits into polyester’s scalable manufacturing system while leveraging low-cost food waste as feedstock.

3. Performance: The patent-pending ALT TEX technology chemically and mechanically optimises the biofibre to mimic the sought-after performance, durability and versatility of polyester.

ALT TEX was founded in 2019 by Myra Arshad, a third-generation textile entrepreneur and 2x startup founder, alongside her best friend, Avneet Ghotra, who has a background in environmental science and biochemistry. Today, the seed-stage startup has grown to a total team of 10 entrepreneurs and scientists with decades of experience in the ALT TEX

biochemistry.

Supported by top Canadian Incubators such as MaRS, The Creative Destruction Lab, Velocity and NEXT over the past two years, ALT TEX has successfully created its food-to-fabric prototype, secured over $2,000,000 in funding, locked in several food-waste donation agreements and welcomed industry-leading advisors from brands like Lululemon and Tentree.

They’re now attracting attention from the global fashion ecosystem with several pilot agreements locked in for their launch over the next couple years on their way to overhauling the $104 billion polyester sector.