- PADT is a globally recognized provider of Numerical Simulation, Product Development, and 3D printing products and services.

- In 2019, PADT celebrated its 25-year anniversary selling and supporting the world’s best engineering software and hardware.

- PADT has offices in Arizona, Utah, California, Denver, New Mexico, and Texas.

- The only ANSYS Elite Channel Partner to serve the entire Southwest, PADT offers a full spectrum of simulation tools and services.

- PADT’s Product Development team is focused on helping companies turn their innovations into real products.

- From desktop protypes to factory floor production systems, PADT offers Stratasys 3D printers with support and maintenance.

Innovation Story

PADT was founded by a group of aerospace engineers who worked together at Allied Signal (now Honeywell Aerospace). The group felt that the tools and skills they used to design, analyze, and prototype turbo-machinery could also be applied to other industries to create innovative products. In the summer of 1994, they joined forces to form Phoenix Analysis and Design Technologies, Inc., now known as PADT.

The first office was a one-person executive suite. They crammed four people and three computers into a tiny room and started calling potential customers. Slowly but surely, work started to come in and the company was off and running. With the purchase of a 3D Systems SLA250 rapid prototyping machine at the end of 1994, PADT became the first independent rapid prototyping service provider in Arizona.

Today, PADT inserts innovation into all that it does, whether that be for NASA, or a local hardware startup with a revolutionary idea. The company was founded on the idea of being the premier provider of “making innovation work,” and it has held that promise for 25 years. PADT focuses on helping customers who develop physical products by providing numerical simulation, product development, and 3D printing solutions. The company’s worldwide reputation for technical excellence and experienced staff is based on its proven record of building long-term win-win partnerships.

The following examples represent how PADT partners with others to advance the greater technology community:

- In partnership with Stratasys and Lockheed Martin, PADT helped to develop next-generation 3D printed parts for NASA’s Orion deepspace spacecraft to Mars. The mission used more than 100 3D printed production parts on board – engineered in union with PADT, Stratasys and Lockheed Martin.

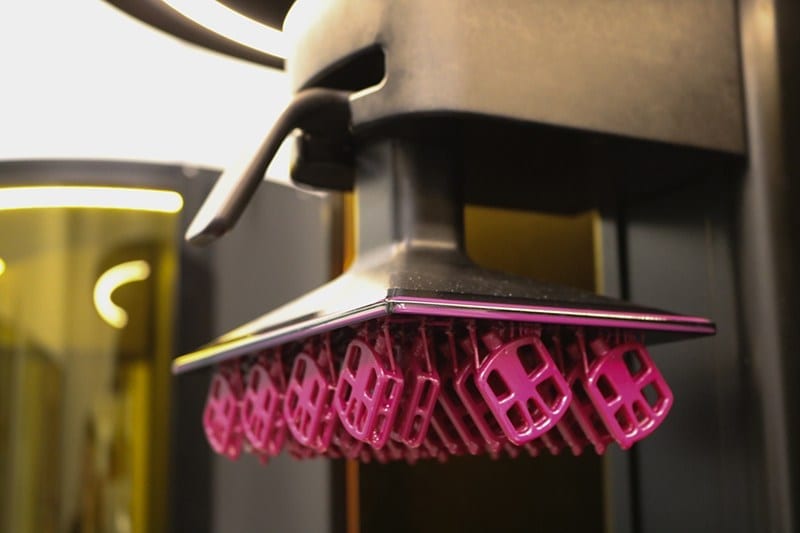

- Realizing the long-term promise of 3D printing replacing traditional manufacturing as a way to make production parts, PADT became a certified production partner of Carbon, a 3D printer manufacturer. The partnership allowed PADT to develop the first 3D printing factory service in the Southwest.

- In additive manufacturing, parts coming off the 3D printers require the removal of support material to be finished. To automate this process, PADT developed and marketed “Support Removal Apparatus” equipment. The product line became the industry’s leading solution and was spun-off into its own company named Oryx Additive.

- $800,000 in matching funds were appointed to Arizona State University, PADT and other partners by America Makes for the advancement of 3D printing post-processing techniques. PADT has been awarded two federally funded projects since 2018, and two America Makes funded projects since 2017.

The company’s body of work, award-winning customer service, and technical excellence has earned PADT the right to serve some of the largest product developers in the world in industries such as medical, aerospace and defense and automotive.

Why Phoenix?

Phoenix has a welcoming attitude towards people. You’re likely to find yourself chatting with an elected official or a top CEO in the Valley. It’s a place where what you bring to the table matters, not who your grandparents were. That’s why Phoenix is filled with smart entrepreneurs with a ‘can do’ attitude.

Advice & Best Practices

Building new relationships is crucial to success. You never know where customers or investment opportunities may come from. Slight improvements in technology no longer push the needle, so take risks and make a splash. Stay focused on matters central to the health of your business. Don’t get distracted by shiny objects.