In the heart of Greenville, South Carolina, Gemba Systems Inc. is redefining what “smart manufacturing” really means. Rather than chasing automation for its own sake, the company focuses on empowering people with smarter technologies – solutions that give manufacturers the visibility, insight, and control they need to perform at their best.

Founded by Stijn Van de Velde, a three-time CEO with more than two decades of experience in manufacturing and logistics technologies, Gemba Systems helps manufacturers increase productivity and profitability through technology-enabled process improvement. Van de Velde is joined by Alain Decartes, Chief Operating Officer with over 30 years of IT/OT leadership, and Joseph Etris, Vice President of IoT Solutions and a recognized expert in Real-Time Locating Systems (RTLS). Together, this team bridges decades of hands-on industrial know-how with cutting-edge digital capability.

“Manufacturing is one of the toughest environments there is,” says Van de Velde. “Our mission is to make it easier for the people who keep it running – by giving them the information they need, exactly when and where they need it.”

From Lean Thinking to Digital Execution

The company’s name reflects its philosophy. In Japanese, Gemba means “the real place” or the “place of truth” where the work actually happens. For manufacturers, that means the shop floor. Gemba Systems meets its customers there, helping them transform operations through Industry 4.0 technologies that connect the physical and digital worlds.

As an Industry 4.0 Solution Partner, Value-Added Reseller, and Integrator, Gemba Systems works with manufacturers to select, deploy, and integrate smart-manufacturing solutions that align with each plant’s unique needs. The firm’s expertise spans Real-Time Locating Systems (RTLS), Advanced Planning and Scheduling (APS), and AR/AI-based operator-support solutions for training, digital work instructions, and tacit-knowledge capture.

What makes Gemba Systems distinctive is its technology-agnostic approach. Rather than pushing one vendor or platform, the team evaluates each customer’s processes, environment, and business drivers to craft solutions that actually fit. “We don’t start with the technology,” notes Decartes. “We start with the problem, and build from there.”

Making the Invisible Visible

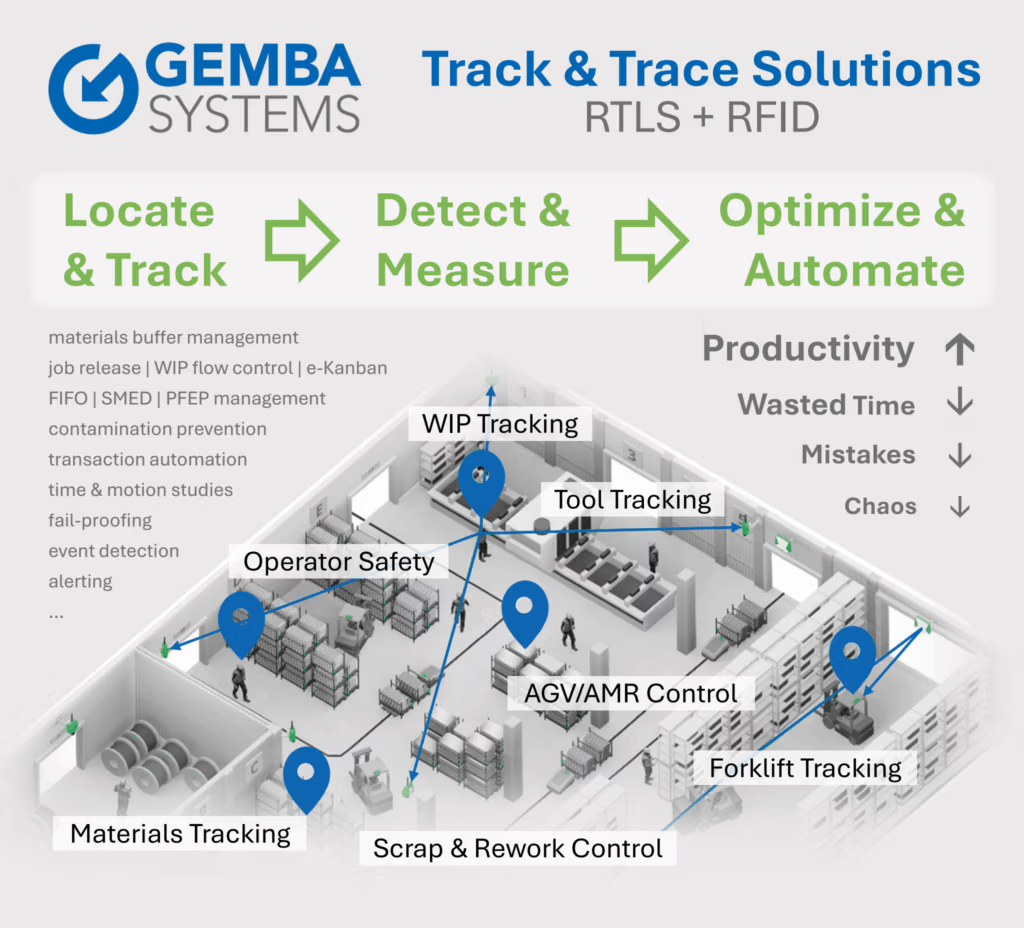

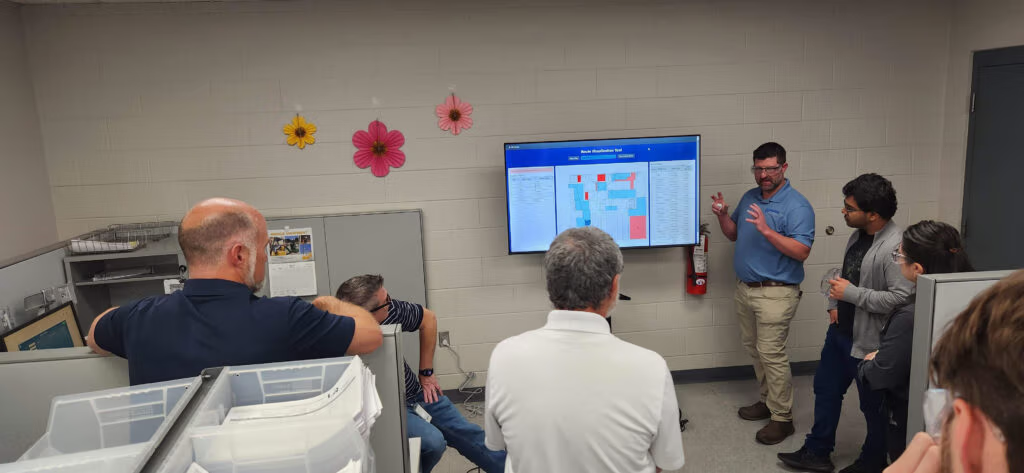

Among Gemba Systems’ specialties, Real-Time Locating Systems have become a transformative tool for modern manufacturing. By combining technologies such as Ultra-Wide band (UWB), Bluetooth Low Energy (BLE), and RFID, RTLS provides live visibility into the precise location and status of materials, tools, equipment, and people across a facility.

With accuracy down to mere inches – even in steel-rich environments – UWB delivers location data robust enough to drive real-time decision-making. BLE systems, meanwhile, balance cost and range for large-area visibility, while RFID and GPS extend tracking to tagged parts, containers, and shipments across sites and continents.

The result is powerful: manufacturers can now see and measure what was previously invisible – how materials flow, where time is lost, and where safety or quality risks emerge. As Etris explains, “When you can identify, locate, and track anything in real time, you can start to detect, count, measure, and ultimately control and improve.”

Solving the Seven Wastes – Digitally

The company’s projects often begin with familiar lean-manufacturing goals: eliminating the “seven wastes” of transportation, inventory, motion, waiting, over-processing, over-production, and defects. RTLS brings these classical objectives into the digital era:

- Transportation: Optimize or automate material-handling routes.

- Inventory: Reduce work-in-process by improving flow and enabling e-Kanban.

- Motion: Standardize work and deploy RTLS-enabled mobile robots for transfers.

- Waiting: Prevent downtime from missing parts or tools.

- Overproduction / Overprocessing: Avoid remaking parts that are simply misplaced.

- Defects: Error-proof operations by ensuring the right part, place, and process.

Beyond these, RTLS also addresses the “eighth waste” – untapped human ingenuity – by equipping teams with data that drives creative, evidence-based problem solving.

Measurable Impact, Fast Payback

Manufacturers adopting RTLS frequently report dramatic improvements. Documented cases show search and walking time cut by 75-90 percent, OEE gains of 3 percent or more, lead-time reductions of up to 50 percent, and rapid ROI – often within 12 months.

Additional benefits include better working-capital utilization, improved asset and forklift fleet management, higher first-pass yield, and greater overall throughput.

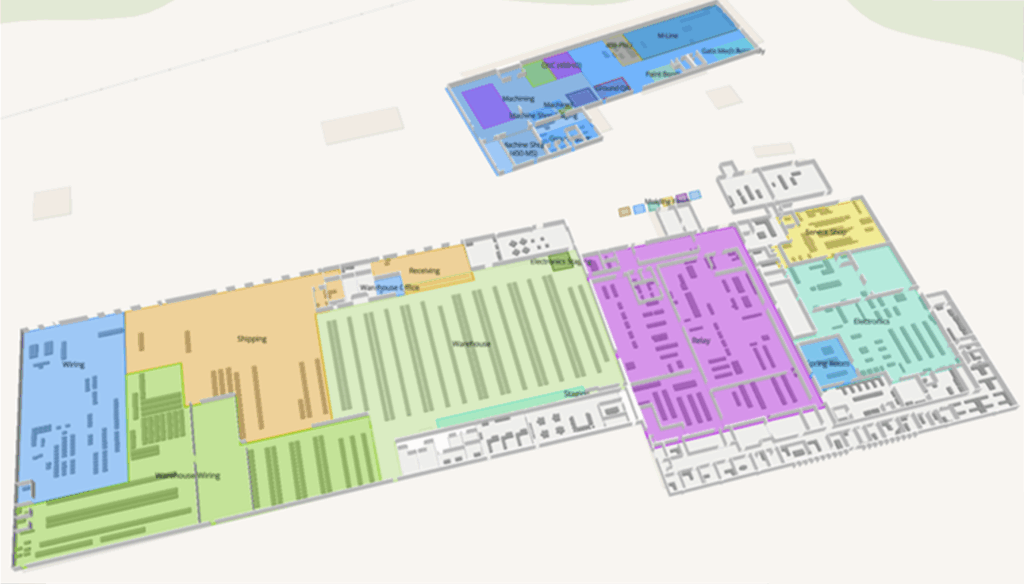

Each RTLS deployment combines tags, anchors or locators, and a positioning server that computes real-time coordinates. Data then flows into visualization and analytics software, providing intuitive dashboards and easy integration with ERP, MES, and Warehouse Management Systems via open APIs and MQTT.

A Partner for South Carolina’s Manufacturing Future

From small, high-mix job shops to major industrial plants, South Carolina’s manufacturers face mounting pressure to do more with less– fewer workers, shorter lead times, tighter margins. Gemba Systems helps them meet that challenge head-on.

“Our state has an incredible manufacturing heritage,” says Van de Velde. “By combining that strength with modern digital tools, we can keep South Carolina competitive for decades to come.”

Whether the goal is better visibility, safer operations, higher OEE, or data-driven decision-making, Gemba Systems delivers the bridge between continuous-improvement principles and Industry 4.0 technology – helping people, processes, and production perform in harmony.