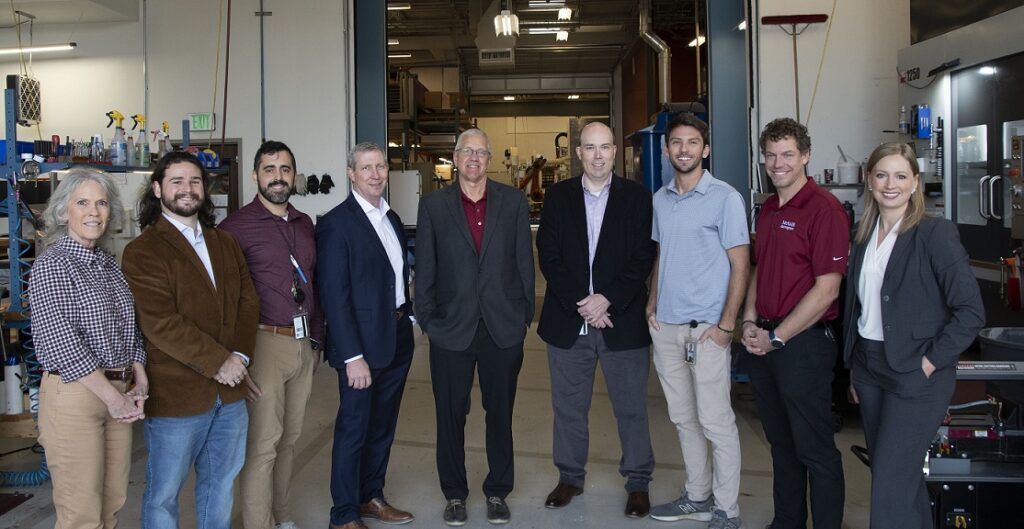

The McNAIR Aerospace Center, in partnership with the USC Molinaroli College of Engineering and Computing, engages university students in innovative, industry-led research in fields such as artificial intelligence, cyber security, automation, 3D printing, and materials manufacturing. This world-class, hands-on education, along with our commitment to cutting-edge innovation, actively creates leaders for the workforce of the future

The center, established with donations from Anita Zucker, Darla Moore, and Marva Smalls and named for astronaut and SC native Ronald E. McNair, has limitless possibilities aiding students to successfully take jobs in South Carolina’s growing manufacturing economy.

Further, Faster, Together.

In a world where technology evolves faster than ever, it is vital that university education also evolve to meet the demand of industry. The McNAIR Center, as a leader in advanced composites research, is a test bed for evolving technology. With world-class machinery, industry partnerships and acclaimed researchers in hi-rate manufacturing, it brings the university engineering students alongside to engage with and spearhead innovation, thus actively growing the state’s knowledge-based economy while meeting the demands of an ever-changing technological landscape.

By the numbers:

7:1 Student to faculty ratio: by design, students receive one-on-one mentoring by experts in their chosen field.

100+ Graduates per year: the need for leadership in manufacturing has never been greater. The McNAIR Center is actively growing South Carolina’s knowledge-based workforce

20+ Faculty advisors: by partnering with the Molinaroli College of Engineering and Computing at the University of South Carolina, our faculty advisors are experts in the field of aerospace manufacturing

$30M in research grants each year: These research grants are the lifeblood of the facility, and provide the money necessary to purchase equipment and train students for the workforce of the future

41,000 sqft – research facility: The layout of the McNAIR Aerospace Center is ideal for collaboration and hands-on research, with research labs conveniently located to shared workspaces and across the street from the Molinaroli College of Engineering and Computing

500 Employed in knowledge-based economy: After more than 10 years manufacturing research, the McNAIR Cente ris proud of the success of its students in the leading the workforce of the future.

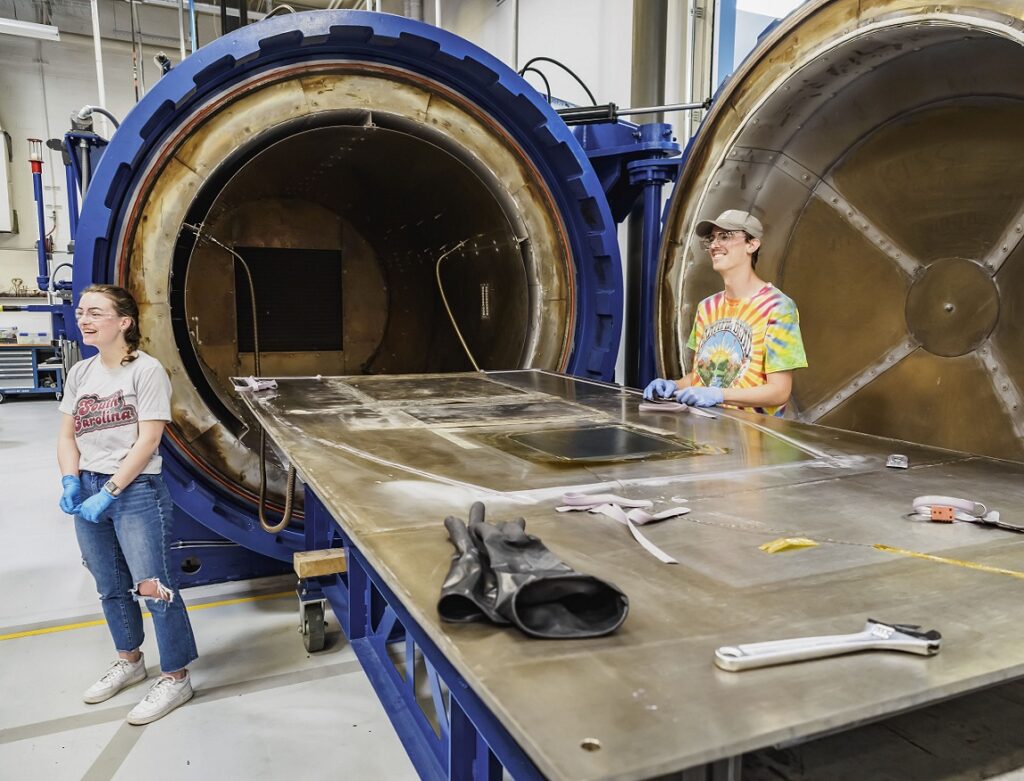

Notable machinery:

• Custom Libra System from Mikrosam

• Bondtech Autoclave

• Wabash Hot Press

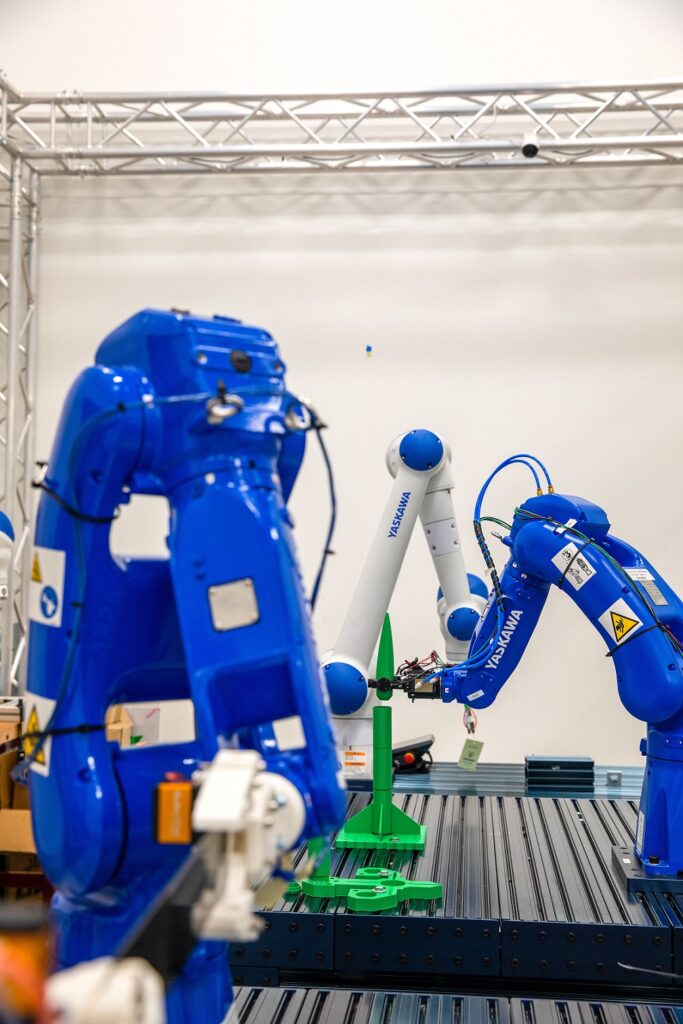

• Robots for 3D-printing, automation, induction welding, and laser inspection (Kuka, Yaskawa)

• More to come!

Core Research

The McNAIR Aerospace Center is focused on the development and supply of engineered materials for high technology industries. Our goal is to provide a foundation of research and development that will enhance growth in the engineered materials field. Our advanced research provides a unique understanding of thermoplastic composites,materials behavior, and design is established with these four, core-research areas.

Advanced Composites

With dedicated research teams and state of the art composite manufacturing equipment, USC is pioneering cutting-edge material development and manufacturing processes for next-generation applications. Our research drives efficiency durability, sustainability, and performance, shaping the future of the advanced manufacturing industry.

Advanced Air Mobility

Our interdisciplinary approach integrates advanced composite manufacturing, aerodynamic design, battery design and implementation and infrastructure. We collaborate with industry to develop sustainable, efficient, advanced-air-mobility, solutions that meet urban and rural transportation needs.

Combustion

Combustion and Propulsion Group at USC is a coordinated to grow a world-class application-driven fundamental research endeavor, encompassing power generation, ground and air transportation, and chemical propulsion using fuels derived from both fossil and renewable energy resources.

Automation

To remain competitive while addressing workforce challenges, USC researchers explore cutting-edge automation technologies to drive efficiency and manufacturing productivity. Leveraging inter-disciplinary expertise and a foundation of aerospace knowledge, we develop workflows, optimize processes, and construct physical prototypes using robotics, AI, and IOT to tackle real-world challenges.

Energy Conversion

The Grid Resiliency Lab specializes in cutting-edge research on high-power, high-voltage, and high-frequency electrical power converters designed for diverse grid-connected applications, including EV chargers, renewable energy systems, and energy storage solutions. The lab is equipped with advanced AC and DC testing capabilities and features a unique 0-13.8 kVAC,300 kVA infrastructure, enabling the prototyping and testing of high-voltage converters under real-world conditions.

Contact

The center supports knowledge-based economy through innovative aerospace research, interdisciplinary education, economic development, outreach and collaboration with the aerospace and allied industries and related government agencies. The center runs on in-kind donations as well as private and government funded contracts. Please reach out to collaborate on future projects in areas such as composites, predictive maintenance, digital transformation, 3D printing, drones and unmanned vehicles, and combustion for aerospace applications.

Ronald E. McNair

A South Carolina native and astronaut aboard the failed Challenger mission, Dr. Ronald E. McNair’s legacy continues to inspire young engineers around the world. Raised in a humble, middle-class family in a segregated society, Ron nevertheless developed a passion for reading and education, eventually receiving a PhD in Physics from MIT. His many accomplishments during his short 35-year life include music, karate, and science, are a testament to his capacity and what one determined South Carolinian can achieve.

“The road between South Carolina and space flight is not a very simple one, nor one filled with guarantees. In fact, the only guarantees to be found are those that reside in the unchallenged depths of one’s own determination.”

– Ronald E. McNair (1950-1986)